Mechanical engineering researchers propose metal powder as fossil fuel alternative

By Design Engineering staff

General Sustainability Energy European Space Agency McGill UniversityMcGill study suggests recyclable metal powders could be as power, energy dense as gasoline.

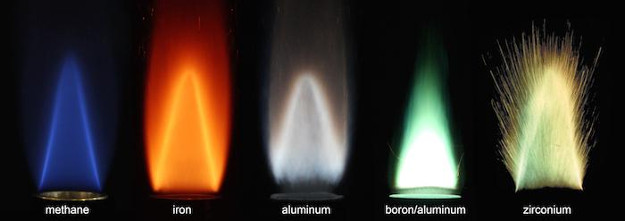

Stabilized flames of different metal powders burn with air, compared to a methane-air flame. (Photo credit: Alternative Fuels Laboratory/McGill University)

“Technologies to generate clean electricity – primarily solar and wind power – are being developed rapidly; but we can’t use that electricity for many of the things that oil and gas are used for today, such as transportation and global energy trade,” says the study’s lead author, McGill University mechanical engineering professor Jeffrey Bergthorson.

“Biofuels can be part of the solution, but won’t be able to satisfy all the demand; hydrogen requires big, heavy fuel tanks and is explosive, and batteries are too bulky and don’t store enough energy for many applications,” adds Bergthorson, who serves as the Associate Director of the Trottier Institute for Sustainability in Engineering and Design at McGill. “Using metal powders as recyclable fuels that store clean primary energy for later use is a very promising alternative solution.”

To demonstrate the concept, the research team used a custom-built burner to stabilize a flame in a flow of tiny metal particles suspended in air. According to the study, the flames from metal powders and those from hydrocarbon fuels “appear quite similar”.

To demonstrate the concept, the research team used a custom-built burner to stabilize a flame in a flow of tiny metal particles suspended in air. According to the study, the flames from metal powders and those from hydrocarbon fuels “appear quite similar”.

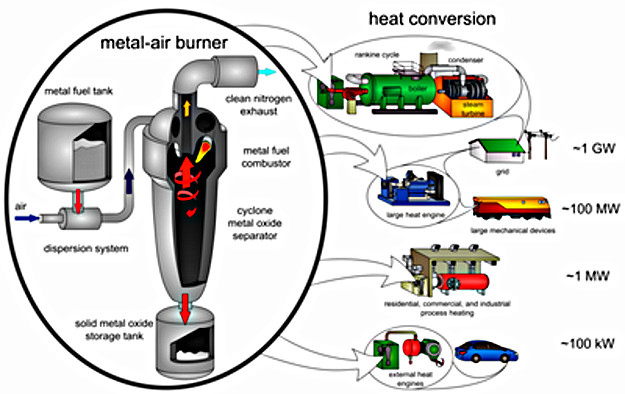

“The energy and power densities of the proposed metal-fueled heat engines are predicted to be close to current fossil-fueled internal combustion engines, making them an attractive technology for a future low-carbon society,” the report says.

If those predictions are correct, the report says metal powders, produced from clean energy sources, could power an external-combustion engine to generate electricity, similar to the process in a nuclear reactor or coal fired power station. In addition to replacing fossil fuels, the metal fuel produces nontoxic solid-oxide as a by-product when burned that can then be collected and recycled.

While technically feasible, using metal powder to fuel a heat engine has so far not been attempted. The McGill research team says the the next step is to build a prototype heat engine. According to David Jarvis, the head of strategic and emerging technologies at the European Space Agency and a co-author of the study, metal powder fuel could have applications beyond power generation.

“We are very interested in this technology because it opens the door to new propulsion systems that can be used in space and on earth,” he says. “The shift away from fossil fuels for vehicle propulsion is a clear trend for the future. While not perfected and commercialized today, the use of low-cost metallic fuels, like iron powder, is a worthy alternative to petrol and diesel fuels. If we can demonstrate, for the first time, an iron-fueled engine with almost zero CO2 emissions, we believe this would then trigger even more innovation and cost reduction in the near future.”

www.mcgill.ca/tised/home