Australian start-up and university partnering to 3D print structures on the moon

By DE staff

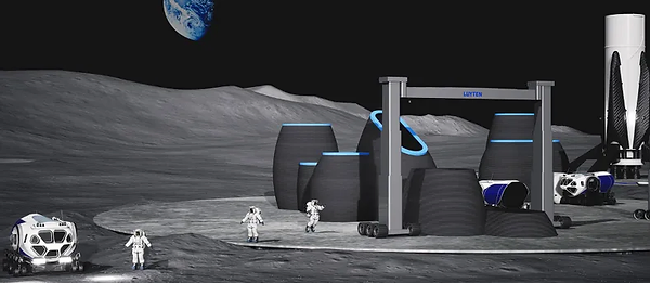

Additive Manufacturing AerospaceLuyten, UNSW researchers look to 3D print buildings from lunar regolith using its 3D concrete printer.

(Photo credit: Luyten)

“When we developed our groundbreaking 3D concrete printers, we thought we would be solving building and construction issues across the world – but with discussions currently taking place with people across the space industry, we are now looking at solving building and construction issues on the moon,” said Luyten cofounder and CEO, Ahmed Mahil.

Called Platypus Galacticas, the company’s envisioned lunar 3D printer will be capable of producing structures up to 9m by 12m in height and length. According to the company, the system will use rovers with ground penetrating radar assess suitable building locations while others harvest lunar regolith. The moon dust would then be delivered to a sorting reservoir where it would be processed to a finer size.

“After sourcing 3D printable material, the Platypus Galacticas 3D printer will start printing on the compacted lunar surface,” Mahil added. “The extrudable materials will then be passed through the printing nozzle and form the layers of the structures.”

According to Associate Professor Matthias Hank Haeusler, the Discipline Director of the Bachelor of Computational Design (CoDe) at the Australian School of Architecture + Design (Built Environment), UNSW, the MOU will ensure the country’s greatest minds are involved in capacity building for lunar construction.

“With Computational design, one has a method to design protective shells for habitats on the moon – with a foremost consideration on requirements for human habitat in mind,” Haeusler said. “Computational design allows to feed in scientific knowledge on how to protect humans from solar and cosmic radiation into a script that generates a shelter with the required 80 plus centimeters of solid material while optimizing the structure towards the print process.”

www.luyten3d.com

www.unsw.edu.au