Burloak adds hot isostatic press equipment to scale-up AM part production

By DE Staff

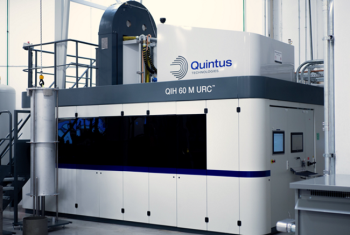

Additive Manufacturing Aerospace MedicalCanadian service bureau’s new QIH 60 HIP set to speed up and reduce cost of metal 3D printed parts.

(Photo credit: Quintus Technologies)

The Quintus HIP performs High Pressure Heat Treatment (HPHT), a required post-processing step when 3D printing metal parts for aerospace, medical and other mission critical industries. In short, HPHT increases part density, relieves stresses in the material and assures that mechanical properties are evenly distributed through the part, among other benefits.

By combining high pressure, heat treatment and cooling in a single process, the Quintus QIH 60 HIP removes several operations from the AM production cycle, saving time and money, the company says. It’s also equipped with the world’s fastest cooling system, with a peak gas cooling rate of > 1500K/min. This rapid cooling under pressure minimizes thermal distortion and non-uniform grain growth in components.

“This capability is critical for Burloak as a full-service supplier for all customers, and, in particular, for the development of high-strength flight components,” comments company founder and Chief Innovation Officer, Peter Adams. “Without this in-house capability, outsourcing this process would slow down our project timelines, add complexity to our processes and risk damaging critical customer components as they would need to be shipped internationally.”

https://burloaktech.com