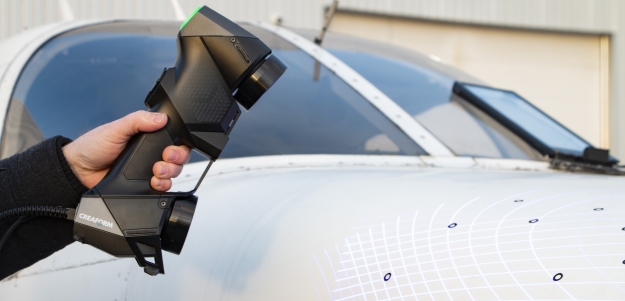

Creaform HandySCAN 3D Scanner Meets Boeing’s Requirements

By DE Staff

CAD/CAM/CAE AerospaceMetrology-grade 3D laser scanner approved to inspect dents and blends on all Boeing commercial airplanes.

Creaform announced that Boeing has released a service letter with guidance on the use its metrology-grade HandySCAN 3D laser scanners for measuring dents and blends on all models of Boeing commercial airplanes. The SmartDENT 3D and HandySCAN 3D scanner were used in the process of guiding Boeing’s quality requirements for the service letter.

Creaform announced that Boeing has released a service letter with guidance on the use its metrology-grade HandySCAN 3D laser scanners for measuring dents and blends on all models of Boeing commercial airplanes. The SmartDENT 3D and HandySCAN 3D scanner were used in the process of guiding Boeing’s quality requirements for the service letter.

“Creaform is proud to see leaders such as Boeing, turn to 3D scanning solutions for surface defect inspection,” said Jérôme Beaumont, Global NDT Business Manager at Creaform. ‟With SmartDENT 3D, our goal is to provide the most accurate damage assessment to our customers, so they can make informed and safe decisions, while getting their aircraft back flying with minimal down time.”

According to Creaform, SmartDENT 3D is up to 80 times faster than the pit gauge technique. In addition, its 3D scanner is accurate to 0.025 mm (0.0009 in.) and has a resolution of up to 0.100 mm (0.0039 in.) with high repeatability and traceable certificate.

In addition to complying with Boeing’s service letter, Creaform HandySCAN 3D scanners are listed in the Airbus Technical Equipment Manual, which is referenced in its Structure Repair Manual. Quality engineers and MRO operators looking to improve their turnaround times and profitability can contact Creaform to find out more about its NDT solutions.

http://creaform3d.com