Dithering process reduces stair-step artifacts in 3D printed parts

By DE Staff

Additive ManufacturingFraunhofer IGD process for polyjet printers minimizes quantization errors to produce smoother part surfaces.

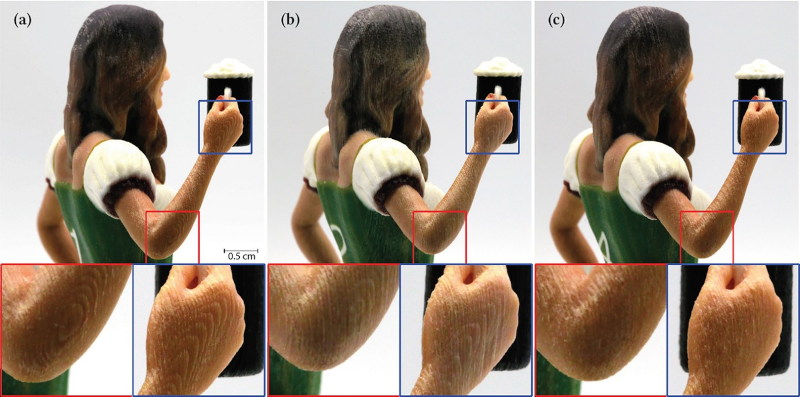

Stair-step artifacts – as visible in image (a) – are not only visually disturbing, but can also be detrimental to printing. Existing techniques for minimizing quantization errors only partially avoid them (b). The new shape dithering method (c), on the other hand, completely removes stair-step artifacts.

(Fraunhofer Institute for Computer Graphics Research)

Stair-step artifacts are unavoidable in conventional 3D printing processes. In addition to being unappealing visually, they can also introduce structural weaknesses to a 3D print.

To generate more accurate surfaces, researchers at the Fraunhofer Institute for Computer Graphics Research (IGD) have developed a new process for polyjet printers. It works by minimizing quantization errors so that stair-step artifacts are no longer noticeable in actual printing and are at a level far below the physical effects of the printing process, the researchers say. This results in objects with a smoother and more uniform surface.

To achieve the desired effect, the surface of the object is modulated with a high-frequency signal, such as blue noise. This leads to a distribution of quantization errors to high frequencies, which are then later removed by the function of the human eye and multiple printing processes.

“The printing time remains the same, regardless of the process,” says Alan Brunton, a member of the three-person Fraunhofer team. “The dithering process does not require additional computing time either.”

According to the researchers, their dithering process can be used as a purely algorithmic method, meaning it can be used with different polyjet 3D printers. In the future, the team says it will investigate if the smoother surface enabled by their dithering process also makes parts more resilient.

The paper presenting the process – Shape Dithering for 3D Printing – was presented at SIGGRAPH 2022 in August..

www.igd.fraunhofer.de/en.html