Dual-phase steel powders developed for 3D printing

By DE staff

Additive Manufacturing AutomotiveGKN Additive’s DPLA and FSLA offer low alloy, DP600-like build materials for automotive and industrial applications.

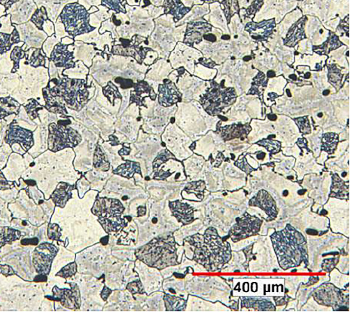

The cross-section of GKN Additive’s FSLA material shows the dual-phase microstructure after heat treatment. The proportion of the different phases and the grain size can be adjusted to achieve unique physical properties, the company says. (Photo credit: GKN Additive)

“With these AM processes, manufacturers in the automotive industry can construct body parts differently than what was possible with traditional sheet metal parts,” said GKN Additive’s technology manager for binder jetting, Christopher Schaak. “If you look at a tailored blank, many sheet-metal parts and support parts need to be formed and joined together to achieve a certain stiffness. By using structural components printed with AM on the other hand, you would need less process steps and less material, leading to cost optimization and a weight reduction.”

According to the company, DPLA and FSLA are more than DP600 (HCT600X/C) simply adapted to additive manufacturing. Instead, the company said the powder materials are specialized for 3D printing with regard to spreadability, laser absorption (laser AM) and sinterability (binder jetting).

“Traditional DP600 offers specific standardized mechanical properties achieved by heat treatment,” Schaak explained. “The dual-phase steel AM materials developed by GKN Additive on the other hand are very flexible in their characteristics, as their mechanical properties can be tuned more widely by the heat treatment after the laser or binder jetting process.”

www.gknpm.com