How and why you should preload a bearing

By Smalley

Power Transmission Machine Building noads

Sponsored by Smalley

Smalley’s guide to bearing preloading and why a wave spring may be the best method.

What do we mean when we say “preload”?

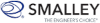

A bearing is designed to move freely and has multiple moving parts that work together as one unit. Tolerance stack up from both manufacturing and assembly can quickly cause issues.

This is where preloading a bearing comes in. Preloading a bearing involves providing a sustained axial load to the bearing.

How do I preload a bearing? Are there different types of preload?

There are two main methods to preload a bearing. The first is solid preload, which is achieved by holding inner and outer races in place with a locking mechanism.

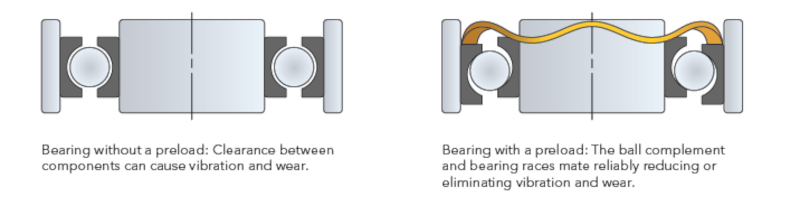

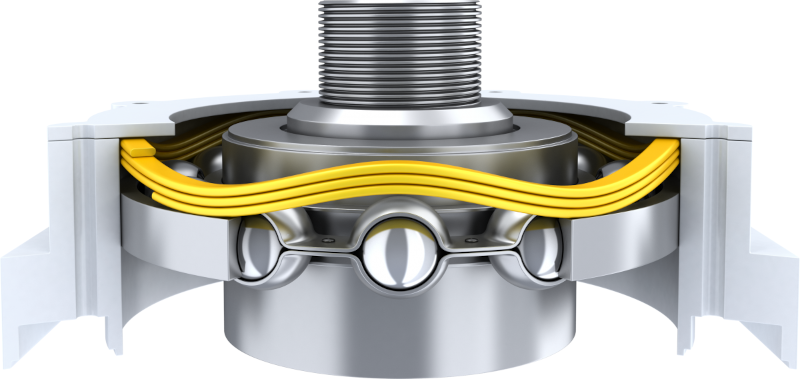

The more common, simpler, and less expensive method is spring preload, which is achieved by using a spring to apply a constant axial load on one side. A Smalley single-turn wave spring provides necessary preload force between the inner or outer races while also compensating for any tolerance stack-ups or thermal misalignments. Play is reduced both axially and radially, as depicted in the image below.

So what’s the big deal, why do we preload bearings?

Controlling play is necessary to maintain bearing functionality and longevity. Preloading a bearing provides constant contact between the bearing type (ball, needle, etc.) and bearing races. The sustained load provided by the spring eliminates axial and radial play, among other benefits. The overall goal of preloading is to prolong bearing life, and therefore, your application.

Advantages of Spring Preload

Properly preloading a bearing will prolong bearing life. Using a spring for preload is critical for high-precision or high-speed applications, as it essentially eliminates the need for holding tighter tolerances and helps withstand high operating speeds.

Benefits

1. Axial and radial play control

Ball complement and bearing races mate reliably and take up dimensional variation.

2. Less wear on bearing

Greater load sharing between bearings due to wave design.

3. Vibration and noise reduction

Quieter assemblies, even in high-vibration applications.

4. Eliminate ball skidding

Constant force is applied for smooth movement.

5. Precise shaft positioning

Wave spring keeps shaft centered for optimal centrifugal distribution.

Selecting a Spring for Preloading

What type of spring should I use to preload a bearing?

Every application is unique, which makes selecting the proper wave spring very important.

It’s important to consider overall tolerances, as placing too much preload on the bearing can reduce longevity, while too little can cause higher noise output in high vibration systems.

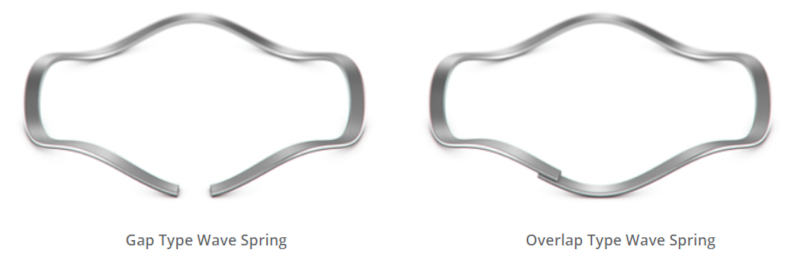

Smalley’s bearing preload wave spring SSB series is carefully designed with the application in mind. The two types of single-turn wave springs we offer are gap and overlap.

As the name suggests, the gap type has ends that are split, while the overlap type has overlapped ends. Both end configurations are free to move around the circumference as the spring is compressed, which is an advantage over traditional wave washers. Wave washers can bind, or become rigid, if pushed into the cavity too much, causing the spring load to become unpredictable.

We have over 300+ standard parts available in carbon steel and stainless steel to match popular bearing sizes. Find your size by checking out the bearing cross-reference table.

If you’re looking for higher force applications, a Nested spring is another type of spring we offer that can accommodate higher preload requirements. A three-turn Nested spring is pictured in the bearing application below.

Additional Resources

As always, our engineering team can assist you in designing a custom preload-bearing spring for your unique application.

- Download or Request Smalley’s Parts & Engineering Catalog

- Request Free Samples to test in your application

- Send us your application requirements, and we’ll find or design the right part