igus shows off variety of products to North American market at IMTS, including their robolink Apiro

Devin Jones

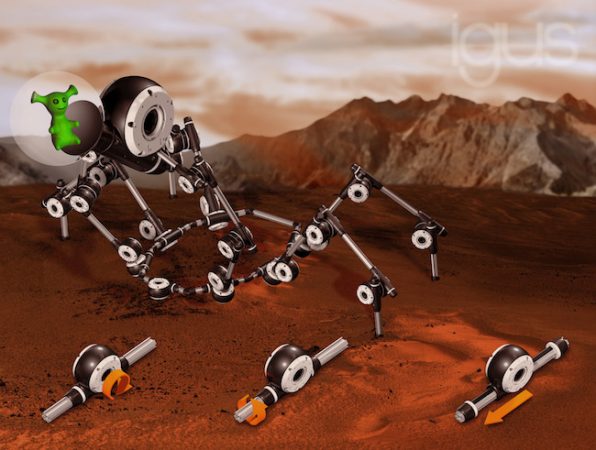

GeneralWith robolink Apiro, design engineers can choose from three lubrication-free worm gears for standard, inverted and linear movement.

The robolink Apiro will theoretically make designing and using individual automation solutions more cost effective and much easier.

With a large presence on the show floor of the International Manufacturing Technology Show, igus showed off their modular motion system, robolink Apiro, which will theoretically make designing and using individual automation solutions more cost effective and much easier.

Although the German-based manufacturing company debuted the robolink technology at the German Hannover Messe show back in April, it’s one of the first time the tech has hit a North American show floor. With robolink Apiro, design engineers can choose from three lubrication-free worm gears for standard, inverted and linear movement. For users, the device offers solutions ranging from the simple linear robot to complex humanoid and animatronic robots.

According to an igus press release the robolink will “allow even complicated movements to be implemented. For example, designers needing parts for individual SCARA robots and linear robots as well as sprue pickers used in removing products from injection molding machines will see benefit in Apiro. Designers of transport and handling systems, as well as humanoid and animatronic robots which can perform movements like those of a spider.”

High-quality tribo-polymers are used in the worm gears of the new Apiro series. The corrosion-free and chemical-resistant high-performance plastics ensure a high degree of stability, low weight, long service life and maintenance freedom.

The joints are combined by a multi-functional profile made of aluminum that makes it possible to insert drive shafts through a hollow space in the middle of the unit. The inverted worm gear makes use of that hollow space.

igus showed off a variety of other products on the IMTS floor, including the ReBel, a low-cost robotics joint that can be used in residential and commercial settings. The idea being serving orange juice, loading dishwashers or sorting manufacturing pieces easier and inexpensive, and the device has the potential to be coupled with a voice command system. From a design perspective, the control equipment is also built into the axes and eliminates the need for an external control cabinet.

“The cables can now be routed directly inside a robot arm,’’ said Martin Raak, robolink product manager at igus GmbH. “Joints can also be equipped with absolute encoders that remember the position of an arm even when a power failure occurs.”

Additionally, igus had their low-cost delta robot on display, provides a simple automation solution for assembly tasks as well as their E-chains for machine cutting.