Fastener Techniques You Didn’t Know You Need

By Mitsumi

General Machine Building Misumi

Sponsored by Mitsumi

How screws become loose and the fastener techniques that prevent it.

“Screws” are the most widely used and imperative components for machine system manufacturing. They are classified by shapes, sizes and strength (class) according to the standards of JIS, ISO etc. In this post, we will cover how screws become loose and measures to prevent them.

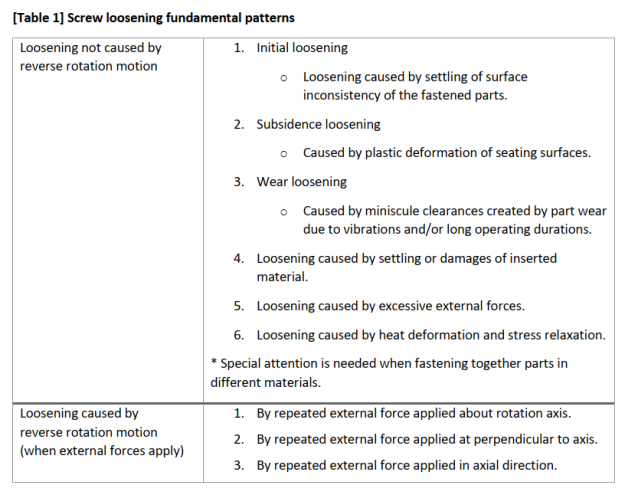

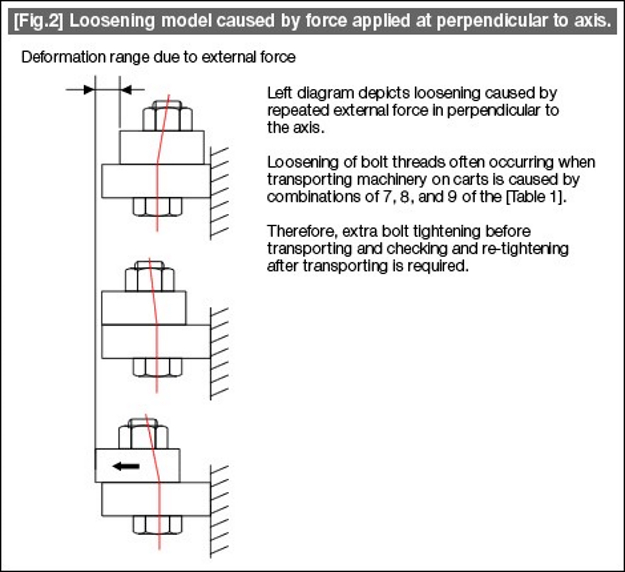

When two parts are fastened with a bolt, tension and compression forces are in a balance where the bolt is elongated and the fastened part material is compressed. If an external force such as shock loads and vibrations apply to this fastening force balanced condition of the two parts, the bolt may become loose.

This bolt loosening may result in equipment damages, defective product production, and critical defects that may lead to accidents. Here are some typical scenarios in which screws loosen and their countermeasures.

Screws Loosening

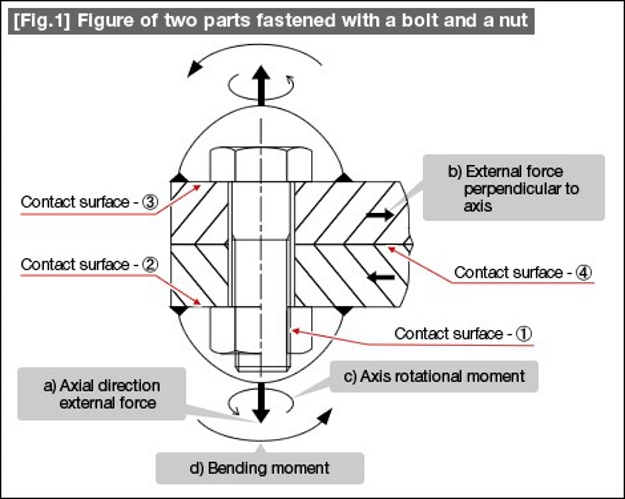

- A bolt fastening two parts may become loose when the following simultaneously occur (see [Fig.1]).

- There are contacting surfaces 1~4 of the two parts being fastened, and external forces are applied.

- There is a clearance between the male and female threads at nut contact 1, and a relative slippage occurs.

- The external forces that affect the bolt loosening are: 4 types shown in [Fig.1] forces a) through d). These external forces cause “Reverse rotation motion” on the bolt resulting in loosening.

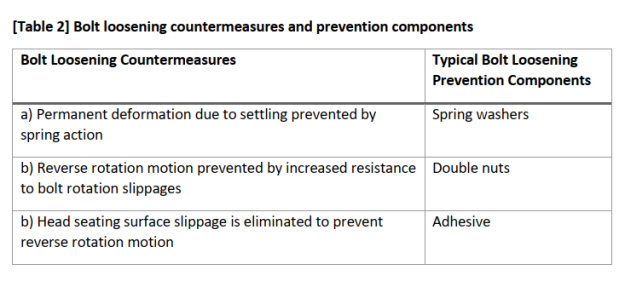

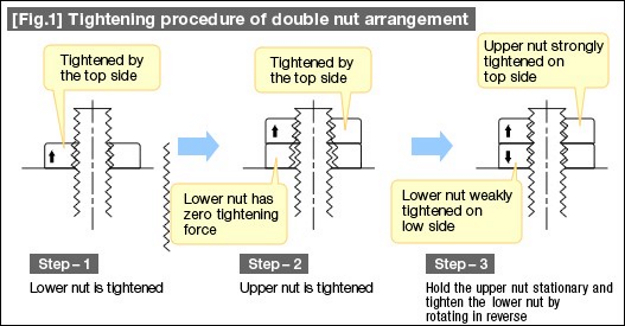

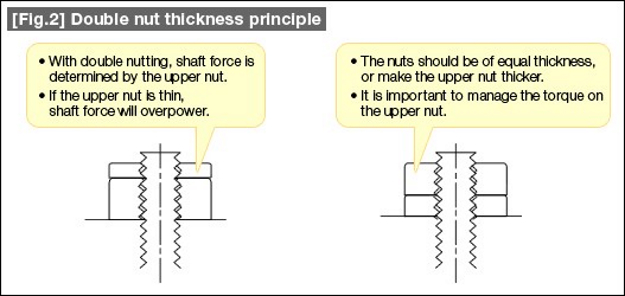

As mentioned previously, one of the more reliable means to prevent screws from loosening is to use “Double nut” method. There are some fundamental points that must be understood regarding this method. [Fig.1] and [Fig.2] are the fundamental rules with double nutting. If these rules are not observed, seemingly reliable implementation will not yield effective results.

Fundamentals of the Double Nut Method

- Effective when the screws may come loose due to rotational force caused by vibrations

- Not effective for loosening caused by material elongation due to material properties.

- Proper procedure is required for double nut tightening. (See [Fig.1])

- The strength of double nut method depends on the strength of the nuts used (principle).

- Thickness of the two nuts used must be carefully considered.

Thread Strength

If used improperly, even the high strength classified bolts cannot guarantee the strength (tensile strength and etc.).

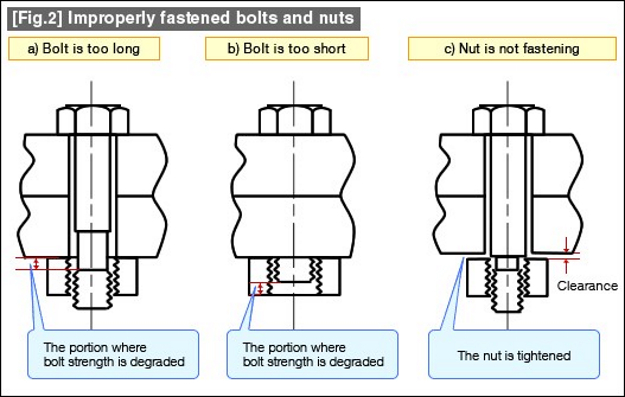

(1) Combination of bolts and nuts

- The fastening strength guarantee values are for usages of bolts and nuts of the same strength classifications used in a normal manner.

- The term “used in a normal manner” means that all the threads of a standard thickness nut are fully engaged with the threads of a bolt ([Fig.1]).

- [Fig.2] shows examples of abnormal usages. The threads of the nuts are not utilized fully.

- [Fig.3] shows examples of excessively long incomplete threads and improper application of shoulder bolts. The subject to be fastened is not properly fastened with bolts and nuts.

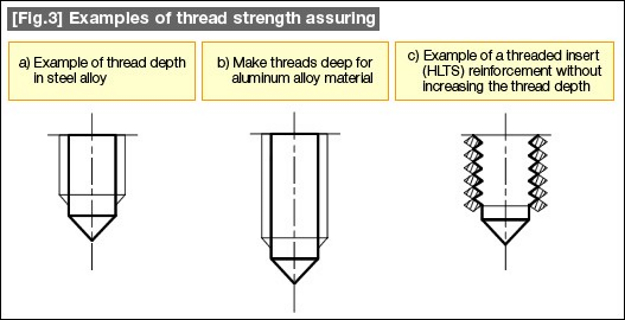

(2) For a bolt and threads

- When bolting a part to a threaded part, the threads must be properly designed depending on the material strength of the threaded part.

Example

- For low strength materials (i.e. aluminum), thread length must be made long in order to ensure ample thread strength.

- If the thread length cannot be made sufficiently long, use threaded inserts for thread reinforcing.

Its important to consider even the smallest fastener in one’s design as you can see there are many force elements that can affect the strength of the bolt hold. Taking these tips and ideas into account can prevent many maintenance issues in the future and bring designs to its full potential.

www.misumiusa.com