New automotive welding technique promises stronger bonds

By Design Engineering staff

Materials Aerospace Automotive Metal Fabrication Ohio State University WeldingOhio State University engineering team says vaporized foil actuator method creates bonds between formerly 'un-weldable' metals.

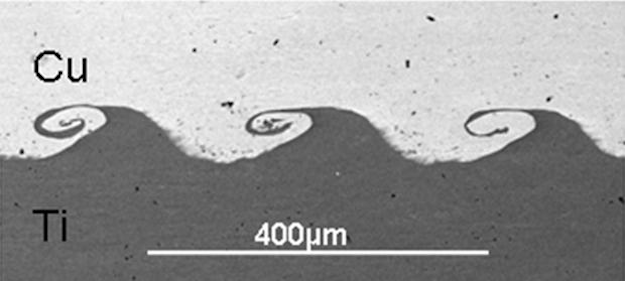

A microscope view of copper (top) welded to titanium (bottom) using a new technique developed at The Ohio State University.

Image credit (Glenn Daehn, courtesy of The Ohio State University).

“Materials have gotten stronger, but welds haven’t,” said Glenn Daehn, professor of materials science and engineering at Ohio State, who helped create the technique. “We can design metals with intricate microstructures, but we destroy the microstructure when we weld. With our method, materials are shaped and bonded together at the same time, and they actually get stronger.”

A diagram showing vaporized foil actuator welding technique.

Image credit (Glenn Daehn, courtesy of The Ohio State University).

So far, the engineers have successfully bonded different combinations of copper, aluminum, magnesium, iron, nickel and titanium, as well as commercial steel and aluminum alloys with weld regions that are stronger than the base metals.

Daehn and his team now want to join with manufacturers to further develop the technology, which will be licensed through Ohio State’s Technology Commercialization Office.

www.osu.edu