New way to bend metals could lead to stronger military vehicles

By DE Staff

Materials DefenseU.S. Army project discovery upends previous notions about how metals deform.

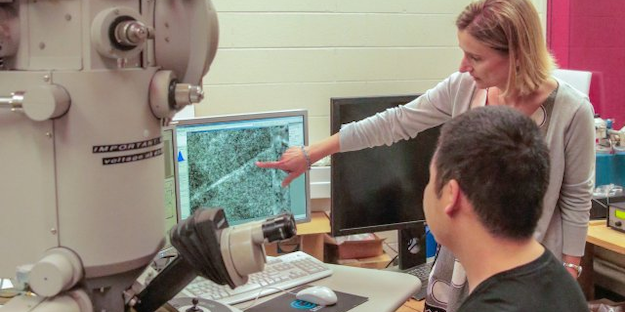

Professor Izabela Szlufarska and postdoctoral researcher Hongliang Zhang at University of Wisconsin-Madison demonstrate new mechanism for bending metal that could help guide the creation of stronger, more durable materials for military vehicles. (Photo Credit: Sam MillionWeaver, University of WisconsinMadison)

“This creates new opportunities for materials design,” said Izabela Szlufarska, a professor of materials science and engineering at UW-Madison. “It adds another parameter we can control to enable strength and ductility.”

Currently, engineers manipulate a metal’s strength through cold working or annealing techniques that exert their effects through small, yet important, structural irregularities called dislocations – tiny irregularities in a metal’s otherwise ordered crystal lattice. Normal metals bend because dislocations are able to move, allowing a material to deform without ripping apart every single bond inside its crystal lattice at once. Strengthening techniques typically restrict the motion of dislocations.

However, Szlufarska and colleagues discovered that samarium cobalt, known as an intermetallic, bent easily, even though its dislocations were locked in place. Instead, bending samarium cobalt caused narrow bands to form inside the crystal lattice, where molecules assumed a freeform “amorphous” configuration instead of the regular, grid-like structure in the rest of the metal. Those amorphous bands allowed the metal to bend.

“It’s almost like lubrication,” Szlufarska said. “We predicted this in simulations, and we also saw the amorphous shear bands in our deformation studies and transmission electron microscopy experiments.”

Next, the researchers plan to search for other materials that might also bend in this peculiar manner. Eventually, they hope to use the phenomenon to tune a material’s properties for strength and flexibility.

“This might change the way you look for optimization of material properties,” Szlufarska said. “We know it’s different, we know it’s new, and we think we can use it.”

www.wisc.edu