NGen funds latest crop of up and coming Canadian manufacturing innovators

By DE Staff

AutomationNon-profit’s $4M in funding supports projects including synthetic spider silk and remote robotic arm operation.

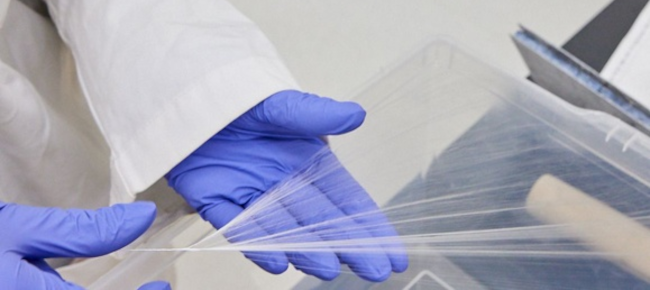

Halifax-based 3D BioFibR develops synthetic spider silk, collagen and other protein-based fibers for medical industrial applications.

(Image credit: 3D BioFibR Inc.)

As the administrator of Canada’s Innovation Supercluster for advanced manufacturing, the non-profit’s match-making and funding efforts help SMEs de-risk advanced manufacturing projects through the development and implementation stage.

Selected by a panel of independent experts, the latest projects approved for NGen co-investment include:

- Halifax-based 3D BioFibR Inc. and biomaterials experts from Dalhousie University are in development of an advanced biofiber manufacturing process capable of producing spider silk, collagen, and other protein-based fibers that have the lengths, linear density, and strengths necessary to be processed using industrial weaving and braiding equipment. Potential products include braided spider silk sutures for microsurgery and woven collagen tubes for nerve repair.

- Moncton, NB-based, Apex Industries, and a partner company are developing a manufacturing process and installation method for manufactured stone veneer panels.

- Vancouver’s Cast Analytics Inc, along with partners Empower Operations Corporation, Surrey, BC, and Applied CCM Incorporated, are developing a software solution for metal casting. The project will create a metal casting digital twin with integrated artificial intelligence driven optimization.

- Mississauga-based Datec Coating Corporation and Process Research Ortech Inc. are developing a chemical manufacturing technology that will produce a third-generation green waste water disinfectant. The disinfectant may also be used in drinking water treatment, industrial effluent treatment and bio-solids remediation, among other applications.

- Lunenberg, NS-bassed Deep Cryogenics International Inc. and North Bay’s Induspec are manufacturing a deep cryogenic treatment tank (DCT) that reduces wear, corrosion and material fatigue in metal alloys.

- Ontario’s Macrodyne Technologies and Ridgetech Automation are developing a technology that will reduce materials and labor costs in the electrical vehicle automotive sector.

- Petra Hygienic Systems International of Concord, ON, and Toronto-based Sidac Automated Systems are building machine vision technology to enable COBOTs for randomized product selection.

- Kitchener’s Quali Artificial Intelligence Inc. and Coquitlam, BC-based Novo Textile have partnered to develop a manufacturing solution that allows an operator to remotely take over the control of a robotic arm. This capability enables one worker to operate and supervise multiple robots remotely.

- Toronto-based Synaptive Medical and MRIdt of London, ON, have partnered to design and build a flexible production line for MRI gradient coils, developing the capability to simulate, optimize and manufacture more advanced gradient coils.

- Additional projects are being led by Hazelett Castechnology ULC (Kingston, ON), Exergy Solutions (Calgary, AB) and Advanced BioCarbon 3D (Rossland, B.C.)

These projects are part of NGen-funded advanced manufacturing initiatives under Canada’s Innovation Supercluster Initiative. To date, NGen has approved investments of $209 million in 135 projects leveraging a total of $515 million in new innovation spending.

www.ngen.ca