Pneumatic Essentials

By DE Staff

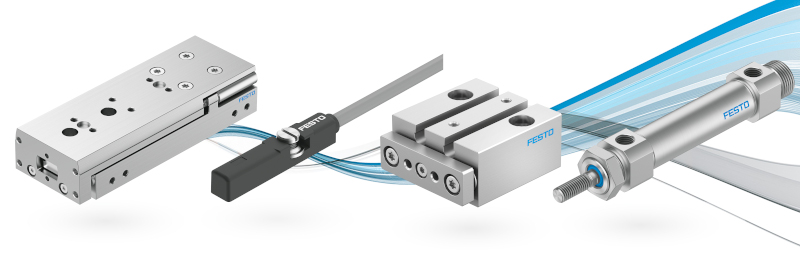

Fluid Power Machine BuildingFesto’s Pneumatic Essentials program designed to simplify order/ship pneumatic products.

Festo has launched its Pneumatic Essentials program, an initiative designed to streamline ordering of 16 of the company’s fundamental pneumatic components. The components include air preparation, polyurethane tubing, one-way flow control valve, high flow valves, self-teaching proximity switch, mini slide, guided drive, ANSI NFPA cylinders, and metric and imperial cylinders. According to the company, expedited shipping is fulfilled by Festo regional service centers; for North America, catalog and customized Essentials components will come from the Festo Global Production Center in Mason, Ohio. In addition to rebranding components, Festo also upgraded existing products and built new lines, including the SDBT-MSX programmable proximity sensor and the company’s compact DGST pneumatic mini slide. In addition, its double-acting ADN-S cylinder is 36% shorter and 20% lighter than similar actuators and its metric DSNU-S cylinder is 40% slimmer, 35mm shorter, 50% lighter than its ISO DSNU counterpart but retains the same bore and stroke length.

www.festo.ca