Protolabs launches automated manufacturability analysis for AM parts

By DE Staff

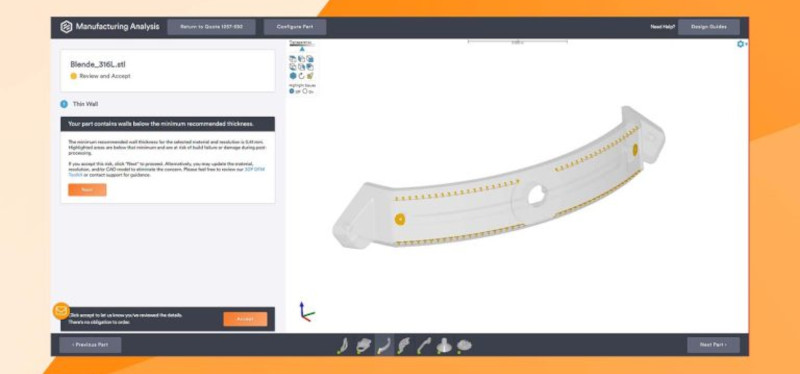

Additive ManufacturingOnline service bureau's DfAM analysis highlights potential design problems before parts are 3D printed.

(Photo credit: Protolabs)

Protolabs announced it has added instant design for additive manufacturability (DfAM) analysis for 3D-printed parts to the company’s online quoting system. The platform provides design feedback on uploaded 3D models to catch potential problems and avoid costly re-prints.

When users upload parts to protolabs.com, the resulting quote includes an analysis that highlights potential manufacturability problems, including thin walls, small gaps and/or parts that exceed maximum size restrictions. Protolabs says its automated analysis system works with both plastic and metal 3D printers and is available through its digital network of manufacturing partners at Hubs.

In addition to analysis, Protolabs has also broadened its additive material and finishing options, in that 3D-printed silicone can be chosen in multiple levels of shore-A hardness. Composed of 100% pure silicone, the build material is biocompatible and functional at a range of temperatures, the company says. Protolabs also recently launched vapor smoothing for select materials, a process that eliminates rough surfaces and leaves a glossy appearance on 3D-printed parts.

www.protolabs.com