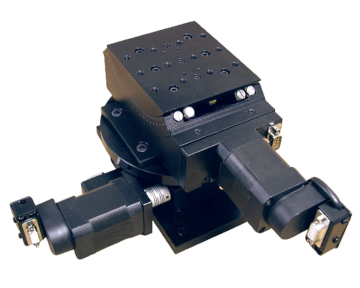

Yaw-and-Pitch Stage

By DE staff

Automation Machine BuildingOES’ YP100-45 series of dual axis stages feature full range of motion of each axis under a single fixed point in space.

OES unveiled its YP100-45 series of dual-axis stages that integrate of a rotary stage (yaw axis) and a goniometer (pitch axis) having a travel range of +/- 45 degrees. The line offers four motor options, including stepper motor driven axes (-01 version), three phase-servo motor driven axes (pictured, -02 version), DC Servo Brushed Motor Driven Axes (-03 version) and stepper motor driven axes with quadrature optical encoders (-04 version) for position verification. The -01 and -04 versions have a maximum speed of 14 degrees per second and have a resolution of 0.001 degrees when 10 micro-steps per step motor drivers are used. The positional accuracy is 0.05 degrees, and repeatability is +/-0.01 degrees. The -04 version has quadrature incremental encoders mounted on the stepper motors for position verification.

OES unveiled its YP100-45 series of dual-axis stages that integrate of a rotary stage (yaw axis) and a goniometer (pitch axis) having a travel range of +/- 45 degrees. The line offers four motor options, including stepper motor driven axes (-01 version), three phase-servo motor driven axes (pictured, -02 version), DC Servo Brushed Motor Driven Axes (-03 version) and stepper motor driven axes with quadrature optical encoders (-04 version) for position verification. The -01 and -04 versions have a maximum speed of 14 degrees per second and have a resolution of 0.001 degrees when 10 micro-steps per step motor drivers are used. The positional accuracy is 0.05 degrees, and repeatability is +/-0.01 degrees. The -04 version has quadrature incremental encoders mounted on the stepper motors for position verification.

For higher speeds up to 45 degrees per second, greater accuracy, repeatability, and resolution, either the YP100-45-02, or -03 Stages should be selected. They are driven by brushed or brushless servo motors with quadrature incremental encoders for closed loop servo operation. The yaw axis is equipped with a HOME switch to signal the motion controller HOME position. The pitch axis has end of limit switched. Both axes have a calibrated scale for visual inspection. The pitch axis table is 90mm by 104mm and has a precision pattern of threaded holes for mounting tooling or fixtures. The large predrilled base plate facilitates mounting in new or existing applications, and adds to the stability of the stage.

www.oesincorp.com