Which is Better: Gear Drive or Belt and Pulley Drive System?

Laura Burgess

Power Transmission Machine Building noads

Sponsored by SDP/SI

The advantages, disadvantages and circumstances that favor one over the other.

A common question that arises when designing an application involving power transmission is, “how will this system transfer motion?” Two of the most popular answers to this question are: A gear drive system or a belt and pulley drive system.

At SDP/SI, our application engineers are asked “which is better?” And just as with everything else in engineering, it depends.

Here we explore both options, the advantages, disadvantages, and circumstances that are better for one over the other.

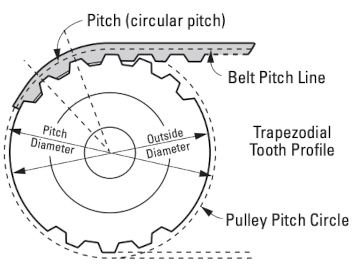

Belt Technology

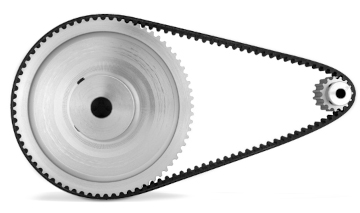

The belt and pulley drive system is one of the most common, there are different types of belt drives, here at SDP/SI two of the main ones are timing belts (synchronous belt) and V-belts.

Both are used to transmit motion from one shaft to another with the help of a thin, in-extensible band that runs over at least two pulleys. It is important to select the right kind of belt drive. V- belts are better suited for high-speed applications while timing belts are better for high torque.

Advantages

Advantages

- Cost-effective

- Simple to use

- No need for parallel shaft

- Come with jam protection

- Load fluctuations are shock absorbed

- Reduce noise and vibrations

Disadvantages

- Not compact

- Greater wear and tear

- Inflict heavy load on shafts

- Angular velocity not constant

- Operating temperature at -35° to 85°C

- Velocity not constant due to V-belt slip

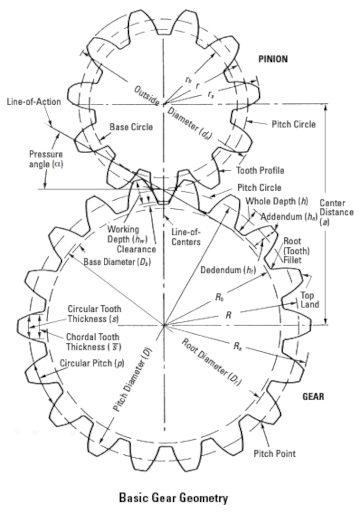

Gear Technology

Gear Technology

Gear drives are probably the first that come to mind when there is a need for power transmission. The process of operation is simple, the teeth mesh with each other to transmit power. There are different types of gears for different purposes, spur gears that work primarily with parallel shafts, bevel gears that work angular, and worm gears that operate at 90° are just a few of the possibilities.

Advantages

- They are non-slip drives

- Mechanically strong

- Deliver high transmission efficiency

- Ideal for low, medium, and high-power transmission

- More compact compared to belts and chains

- They can transmit motion over small center distance of shafts

Disadvantages

- Cannot be used for shafts with large center distances

- Not ideal for large velocities

- Need regular lubrication

- Multiple gears raise machine overall weight

- They have no flexibility

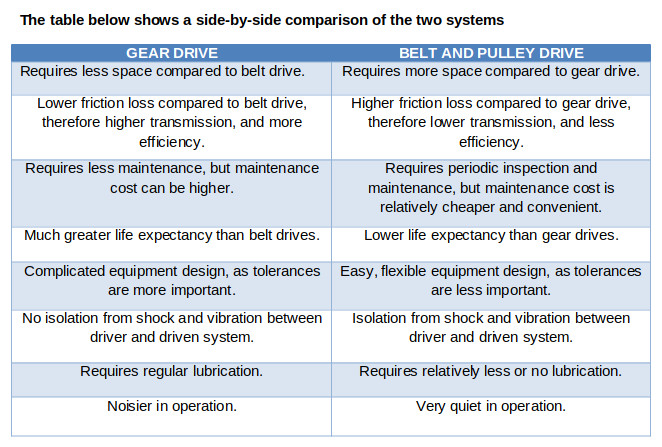

To conclude, what system is best depends on your application needs, as shown each system might be great in one scenario but weak in another. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In general, for smaller drive systems gears are less costly than a belt and pulley system, but in large applications a timing belt and pulley drive system is more cost effective.

There you have it – hopefully this discussion as to advantages and disadvantages of each drive system has helped. Still not sure which system is right for your application? SDP/SI engineers assist with problem solving solutions daily, from custom design to part selection – we look forward to working with you! Call Us (516) 328-3300.

Engineering Development, Precision Manufacturing, Stock Components, and Custom Drive Systems – One Single Source, SDP/SI.

https://sdp-si.com/