Making the Link

By DE Staff

Automation Motion Control Machine BuildingHow IO-Link simplifies the installation, configuration and maintenance of field devices.

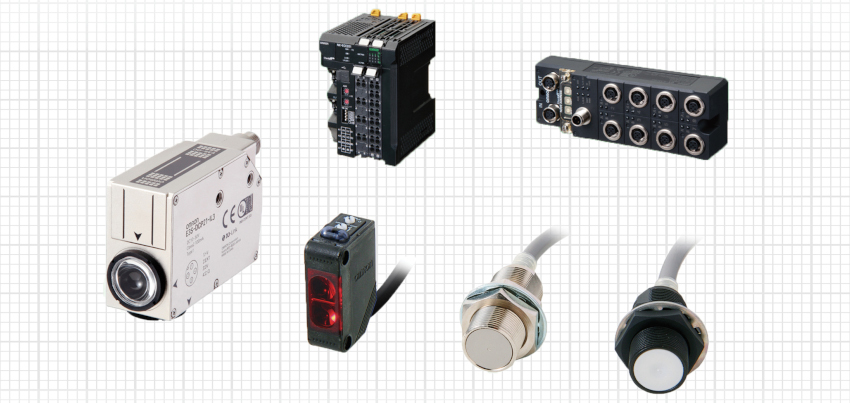

(Photo credit: Omron)

In that role, he works with Omron’s development team and his North American colleagues to aligned the company’s products to the U.S. market, primarily remote I/O products for the automotive sector.

Can you give an overview of IO-Link?

IO-Link has been around for a few years, but it’s just starting to be adopted by a lot more users in the automation field. As an overview, IO-Link is a standard communication protocol for field devices, such as sensors and actuators, that allows for additional data transfer between the device and the controller than was normally possible before.

In addition, IO-Link uses the same wiring as a typical sensor, so cables with M12 connectors and four or five wires. This really simplifies the wiring, because you don’t need to use anything special. Also, more manufacturers are making devices that are IO link.

The advantages of implementing IO link are really just going up. Nowadays, many devices that were typically analog before are available in a lower cost IO-Link version. This greatly reduces system costs and lowers the chance for signal errors when connecting longer cables.

And now we’re starting to see manufacturers make things like IO-Link robot grippers, as well as stock lights, motors, encoders, pneumatics, and you name it. Think of a field device for automation and there’s probably an IO-Link version of that now.

How do IO-Link sensors differ from common ones?

The typical sensor is digital, 3- or 2-wire and non-smart. That is, there’s no data communication from the PLC or the controller to the sensor. The issue is if there’s any problem with that sensor, the controller doesn’t know; the sensor either gives the output correctly, or it doesn’t. The only way to know there’s an issue with a sensor is if the machine crashes or product gets missed.

For 3- or 4-wire analog sensors, it’s the same thing. Either the signal drops or it doesn’t, but there’s no communication back and forth.

What IO-Link does is it allows the controller to talk to the device and get additional data transfer back and forth. You can also access different data points from the sensor. For example, you can get not only the temperature from a sensor, but also the intensity of the signal, to see if it is weakening. You can write settings to the device as well.

Say you have a complicated device that takes maybe three or four different settings on the device to get it dialed in for your application. Typically, you’d have to either set all those with a potentiometer directly on the device, or you’d have to click on a menu.

With IO-Link, you can program directly from the controller. So you can send a message to it, say, I want these settings, and you can write to it. This saves a lot of time, because it might a maintenance user’s first day on the job or it might be their first time replacing this type of sensor and they don’t know how to configure it.

Is the IO-Link protocol hardware agnostic?

IO-Link is a standard protocol. Field devices connect to an IO-Link master, which connects to the system fieldbus. The master converts from IO-Link to whatever protocol you’re using for your application, whether it’s Ethernet IP, EtherCAT, Profinet, Modbus, etc. So you would purchase an IO-Link master that can talk to your fieldbus.

And it will work with any IO-Link device by any manufacturer, which can connect to any master by any manufacturer. If you look across all the manufacturers making IO-Link masters and devices, pretty much all major protocols are covered.

What is the best way to use IO-Link?

I’d say the first thing I would look at is any expensive device, particularly if they’re analog, and getting that analog signal via IO link instead. Digital is typically less expensive than analog.

Then, I would look at any problem area devices. If you have certain parts of your line, or a machine, that has issues, you can utilize IO-Link to get that data and get an idea of what’s going wrong. Maybe the sensor is getting dirty, or maybe the end user is bumping into it, that kind of thing.

And lastly, for any device that has multiple parameters that need to be set, consider using IO-Link to help the user replace that easily. In IO-Link, there’s a thing called backup and restore. So you can set up the device, and then back those setting up inside the master.

If you’re the OEM, you know exactly what you want to set this device to. You can back those settings up into the master, and then all the end user has to do is replace the sensor or field device and the IO-Link master automatically restores those saved parameters to the replacement.

That’s particularly good for devices that have multiple set points and multiple different settings, like distance laser sensors. They’re very good for complicated applications, but there are a number of different settings that need to get dialed in just right. To have an end user do that correctly, when they replace it, is probably pretty difficult. So having backup and restore is going to be very critical for those kinds of devices.

The cost saving enabled by being able to diagnose problem areas quickly and performing preventative maintenance, plus the time saving afforded by IO-Link’s automatic backup and restore function are the main benefits of IO-Link. Even so, we have yet to see full extent of what manufacturers, OEMs and machine builders will come up with using IO-Link..

What are the downsides of IO-Link?

For a lot of people I’ve talked to, it still takes some configuration time for the programmer to set up. They’re already used to setting up a digital device so, for them, it’s a lot easier to use a digital device. It can also be less expensive than an IO-Link one. So they think, I don’t need to go through the extra hassle of IO-Link when my customers aren’t asking for it.

What customers are asking for, however, is less downtime, more reliability and easier maintenance. So end user may not be asking to use IO-Link, but they are asking for those keywords. Those are all clues that maybe you should consider IO-Link, because it’s a small investment upfront, once you learn how to use it.

I’d heard of a situation recently, where the end user wanted the OEM to stand by the output and productivity of the machine and offer maintenance as a package. IO-Link allows that OEM, or the system integrator, to guarantee a certain output, because they’re able to remotely understand what’s going on with the system. I think IO-Link opens additional business opportunities, in that an OEM can offer maintenance as a service or rent the machine as opposed to selling it.

Besides sensors, what other devices are available with IO-Link?

What I’m seeing is customers considering IO-Link to use with robot grippers. Typically a gripper would be a serial communication, like RS-485.But on a robot cell, there’s remote IO and remote IO is IO-Link.

That allows you to mount one master on the robot and have all your sensors going to it, as well as the robot gripper. You don’t have to worry about RS-485 anymore, which simplifies a lot of things.

Currently, a lot of manufacturers are making anything that can be communicated with as a candidate for an IO-link option. For example, pneumatic companies are making IO -Link devices, like valves and valve banks. Stack lights are another, which you can trigger to be different colors.

Also, Omron makes a safety light curtain, from which you can get the beam data to see if its getting dirty. There are also IO-Link encoders, VFDs and motors. The doors have really been open now that more and more customers are using IO-Link.

www.omron.ca

This interview was adapted from an episode of the Design Engineering podcast.