From Screen to Shop Floor

By Treena Hein

General Machine BuildingMontreal-based Vention applies AI, online CAD and e-commerce to the custom machine building industry.

It’s often said but Vention – a Montreal startup that allows customers to design and order custom industrial machines online – really has experienced a meteoric rise since its founding in 2016.

It’s often said but Vention – a Montreal startup that allows customers to design and order custom industrial machines online – really has experienced a meteoric rise since its founding in 2016.

In 2019 alone, the Montreal-based company has nearly doubled it workforce (from 28 to 55 employees), raised $17-million in venture financing and grown by 600 percent compared to 2018. In addition, the young firm already counts the likes of Tesla, Facebook, BMW and Bombardier among its high-profile clientele.

So what’s attracting so much attention in such a short amount of time? According to electrical engineer and Vention’s head of automation, Francois Giguere, the company’s novel technology and business model removes much of the complexity and cost from the process of automating a manufacturing process.

“Traditionally, people build machines by sourcing parts from various vendors and trying to make it all work together,” explains Giguere, who has been with the company since its beginnings in late 2016. “We focus on machine design holistically and offer a platform where everything is designed to fit together and do what it’s supposed to.” He says that, in most cases, that’s very hard to perform due to cost and technical complexity.

In essence, Vention’s platform allows customers to log in through a browser and start building an automated machine using a large online library of virtual ‘building blocks’. Those blocks include everything from standard aluminum extrusion, mounts and fasteners to motors, drives, sensors, conveyors, actuators and other common components from Vention’s industrial suppliers.

Instead of a traditional PLC, motion control is managed with Vention’s MachineMotion, a Linux-based plug-n-play motion controller designed to work with all components in Vention’s parts library. Adding it to a design gives access to MachineLogic, an online motion programming environment. Users can run simulations and add the validated code to the MachineMotion before shipping.

This design work is all performed within the company’s browser-based MachineBuilder 3D CAD environment and stored on its cloud platform. During this process, the application keeps a running tally of costs and bill of materials.

After the design is complete, validated and purchased, a kit including all the necessary parts is delivered to the customer’s door anywhere in the world, typically within a matter of days, the company says.

“For most of my career, you would need to visit 15 different websites searching for parts and praying that there were 3D models of those parts online, ordering everything and then assembling it in the hope that it all fits and works,” explains Vention co-founder and CEO Etienne Lacroix who spent his career in the constant pressure cooker of designing custom machines.. “It would take anywhere from six weeks to six months to finish a machine. Machine integration is really, really complex and it takes the most talented engineers you can find.”

But despite all the advancements out there, Lacroix notes that in terms of integration and machine building, even the best industrial companies still have ‘tech stacks’ from the 1990’s.

As for small manufacturers, he says it’s pretty much impossible for them to afford the cost of an integrated automated machine for one of their processes. Unless you’re producing a significant volume, the required investment can’t be paid off.

“We can typically do the whole thing ‘by Friday’ and for less than $30,000, and that’s an ROI for many of our clients of a few months,” Lacroix adds. “What I’m most proud of with Vention is that machine designers, who know the basics but are not full-time system integrators, can work with us to actually make what they need. It’s a true democratization of machine design.”

Genesis

The idea for Vention first occurred to Lacroix in 2014, after reading about the latest advancements for WebGL. At the time, the graphics library was just getting good enough to render engineering-grade 3D graphics in a browser. These developments got him to thinking about a whole new way to do machine integration.

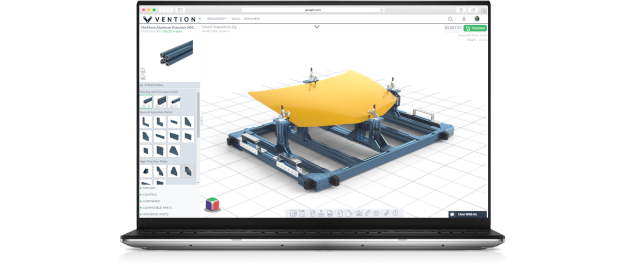

Designed in Vention’s online CAD app MachineBuilder, this machine is build from components in the company’s 500 part library, including the it’s own plug-n-play MachineMotion controller.

By February 2017, Vention had 70 component options available for integration. At that point, the software was also limited and the library of customer-contributed designs was also obviously very small.

“We had to work on all those things in parallel, for the first users to see benefit,” Lacroix explains. “My co-founder and CTO, Max Windisch, and I worked 19 hours a day for a year and a half and the rest of the team also worked very hard. Now we have over 500 parts and a library of over 700 designs.”

Lacroix describes himself as a kid who had more Lego than all the other kids in the neighborhood combined. He likens Vention to an industrial Lego set for all their customers, which range from small manufacturing shops to large multi-nationals.

“We amaze the big players most of all with speed,” says Lacroix, “and the small ones most of all with cost.”

Currently, Vention serves about 1000 customers a month, including a significant number of repeat customers.

Maintaining Simplicity

Building Vention has been a matter of building three companies in one, Lacroix explains. There’s the software (which he describes as 3D CAD platform in a web browser), the Vention library of modular industrial parts and supplier parts and a parallel e-commerce system.

“We grew the platform from scratch,” notes Giguere, “and while it guides users towards what’s possible, it’s always been the challenge to keep it simple so that people who aren’t design experts can make a range of applications.”

“Our community is very vocal, and we have dedicated staff members to handle feedback and divert it to the appropriate engineers,” he adds. “But we also work steadily ourselves to figure out how different components could be compatible with others, and new components are coming out all the time. So, the platform software team works with the real-world team and everything evolves.”

Lacroix echoes the sentiment. “We will reach 5000 parts, I have no doubt, but keeping the simplicity is critical,” he says. “One way of keeping simplicity is to recommend next-best parts. I call it machine learning meets machine design. There are also many ways that things can be connected, so the platform suggests the best one. This enables a user to usually connect two parts in one mouse click.”

Vention also provides tools that self-optimize the cost of a design, and a secure link to the design can be sent to different departments in the same company.

Collaboration is assumed, like Google Docs, Lacroix explains. Customer team members can all have access to the design, past orders and more.

Like the challenge of keeping simplicity, what Lacroix and Giguere both like best about their work hasn’t changed much over time: The consistently positive response from Vention customers.

“When we help them come up with a system and we present it to them, they are surprised and very thrilled,” Giguere says. “To have a service that enables them to go so fast and do what they need to do so easily, they are just amazed.”

www.vention.io

Treena Hein is an Ottawa-based freelance writer.