Montreal engineers’ 3D printed webbing absorbs 96% of impact energy

By DE Staff

Additive Manufacturing MaterialsPolytechnique Montréal researchers say material could be used to make bullet-proof glass or unbreakable cellphone screens.

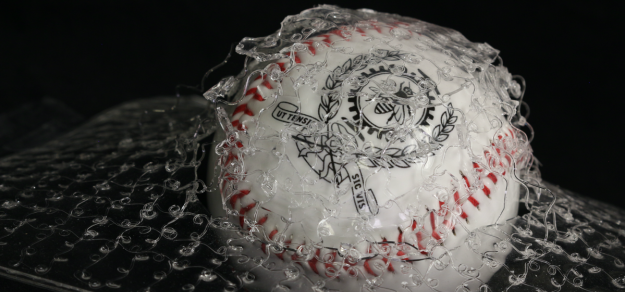

Polycarbonate webs synthesized using additive manufacturing absorb up to 96% of impact energy. (Photo: Shibo Zou)

“A spider web can resist the impact of an insect colliding with it, due to its capacity to deform via sacrificial links at the molecular level, within silk proteins themselves,” Professor Gosselin explains. “We were inspired by this property in our approach.”

The Polytechnique Montréal researchers used a 3D printer and a polycarbonate build material to create a series of 2mm thick fibres quickly followed by a separate set of fibres laid perpendicularly to the first set before the entire web solidified. As the 3D printer extruded a fibre, the molten plastic formed a series of loops.

“Once hardened, these loops turn into sacrificial links that give the fibre additional strength,” researcher Gosselin explains. “When impact occurs, those sacrificial links absorb energy and break to maintain the fibre’s overall integrity – similar to silk proteins.”

According to Gosselin, their plastic webbing could lead to the manufacture of a new type of bullet-proof glass, or the production of more durable plastic protective smartphones screens. “It could also be used in aeronautics as a protective coating for aircraft engines,” the Professor Gosselin notes.

A study detailing the process appeared in the latest issue of Cell Reports Physical Science journal.

www.polymtl.ca