Small Package, Big Energy

By Velo3D

Additive Manufacturing EnergyMohawk Innovative leverages 3D printing to boost durability, slash cost of SOFC fuel cell components.

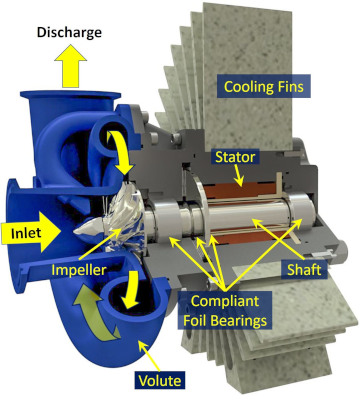

Mohawk Innovative Technology’s anode offgas recycle blower (AORB) recycles unconsumed hydrocarbon fuel to the front of solid-oxide fuel cell (SOFC) for reuse.

(Photo credit: Mohawk Innovative Technology Inc.)

Of course hydrocarbons release pollutants when burned, but what if you never ignited them? A promising approach, now emerging from the research stage into commercialization, is solid-oxide fuel cell (SOFC) technology. According to its website, the U.S. Department of Energy (DOE) has invested $750 million in SOFCs since 1995, as part of the ongoing effort to decarbonize energy production.

The DOE describes an SOFC as an electrochemical device that produces electricity directly from the oxidation of a hydrocarbon fuel (usually natural gas), while eliminating the actual combustion step. Basically, an SOFC acts like an infinite-life battery that is constantly being recharged – without burning the gas that recharges it.

“Solid oxide fuel cells are very attractive because they produce a lot of energy in very small packages,” says Jose Luis Cordova, Ph.D., VP of Engineering at Mohawk Innovative Technology Inc. (MITI). The 28-year-old, Albany, New York-based company specializes in “CleanTech” – the design of high-efficiency, environmentally low-impact, oil-free turbomachinery including renewable energy turbogenerators, oil-free turbocompressors/blowers, and electric motors.

“SOFCs are compact and can be built at a factory, then transported to the specific site where they’re needed to support distributed-energy production,” he adds. “SOFCs are also very efficient. Unlike a regular battery, they don’t lose power over time because, as long as you supply the reagents, you can continue the electrochemical reactions pretty much indefinitely.”

Sounds ideal, and more than 40,000 units of 100-kilowatt fuel cells were shipped worldwide in 2019. But there have been bumps in the road. Many SOFC components are expensive to manufacture and, due to exposure to the very gases that make their operation so efficient, they wear out frustratingly quickly.

Facing issues

To help overcome these challenges, Mohawk has designed some of those critical parts for longer lives and greater efficiency. One example is the anode offgas recycle blower (AORB), an essential component of the “balance of plant” machinery that supports the SOFC’s fuel stack.

During operation, each fuel cell only uses about 70% of the gas it’s fed; some 30% passes right through the system along with water (a product of the electrochemical reaction).

“That’s where the AORB comes in,” says Cordova. “It’s essentially a low-pressure compressor or fan that recycles the exhaust and returns it to the front of the fuel cell.”

“SOFC balance-of-plant designers were thinking that this blower would be an off-the-shelf unit,” says Cordova, adding that a typical 250 kW SOFC plant would employ two of them. “But due to the process gases in the system, traditional blowers tend to corrode and degrade; the hydrogen in the mixture attacks the alloys the blowers are made of and also damages the magnets and electrical components of the motors that power the blowers. Most blowers also contain lubricants, like oil, that degrade as well. So you end up with very low-reliability blowers – representing a significant portion of the balance-of-plant cost – and your SOFC plant needs an overhaul every two- to four-thousand hours.”

This statistic falls short of the DOE’s goal of an operating lifetime of 40,000 hours for a typical SOFC – as well as an installation-cost reduction from $12,000/kWe (kilowatt of electrical energy) to $900/kWe.

“So we realized that Mohawk’s proprietary, oil-free, compliant foil bearing (CFB) technology, specialized coatings and decades of turbomachinery expertise were a good fit for this challenge,” says Cordova.

Turing to AM

In addition to the company’s foil bearings, its AORB blowers also incorporate a custom designed impeller, 3D printed in corrosion-resistant Inconel 718.

(Photo credit: Mohawk Innovative Technology Inc.)

For longest life, this part must be made from expensive, high-strength, nickel-base, corrosion-resistant superalloy materials like Inconel 718 or Haynes 282 that are difficult to machine or cast. In addition, achieving optimal aerodynamic efficiency in an impeller requires complex three-dimensional geometries that are a challenge to manufacture. And because of the incipient nature of the current SOFC market, impellers are produced in relatively small batches, and economies of scale are difficult to realize.

A nice price surprise

To bring that cost down, additive manufacturing provided a compelling answer. Cordova says, the company did its own research into AM system makers and decided on laser-powder-bed fusion (LPBF) provider, Velo3D. By switching to AM, he says the cost of manufacturing impeller wheels declined from $15,000 to $19,000 apiece to $500 to $600, when 3D printed in small batches of around eight units.

“As well as cutting manufacturing costs, LPBF is the one technology that could provide us with the design flexibility we were looking for,” he says. “AM is indifferent to the number of impeller blades, their angles or spacing – all of which have a direct impact on aerodynamic efficiency. We now have the geometric precision needed to achieve both higher-performance rotating turbomachinery designs and reduce associated manufacturing costs.”

For 3D printing impellers on a Velo3D Sapphire system, the choice was made to use Inconel 718 – one of the nickel-based alloys with a strong temperature tolerance that withstand the stress of rotation best. Although Velo3D had already certified Inconel 718 for their machines, Mohawk did additional material studies to add to the body of knowledge about the 3D-printed version of the superalloy.

According to Mohawk, switching from 5-axis machining to 3D printing reduced impeller production cost from $19,000 apiece to $600.

(Photo credit: Mohawk Innovative Technology Inc.)

As their impeller work progressed, Mohawk’s engineers collaborated with Velo3D experts on design iterations, modifications and printing strategies.

“It was really interesting because we didn’t have to make any major design changes to the original impeller we were working with. With Velo3D’s Sapphire system we could just print what we wanted,” says Cordova. “We did do some process adjustments and tweaking in terms of support-structure considerations and surface-finish modifications.”

As the impeller project progressed, AM provided much faster turnaround times than casting or milling would have allowed, since parts could be printed, evaluated, iterated and printed again quickly. In subsequent 3D printing runs, multiple examples of old and new impeller designs could be simultaneously made on the same build plate to compare results.

Sacrificial shrouds

The relatively small size of the impellers (60 millimeters in diameter) necessitated the team’s development of a “sacrificial shroud” – a temporary printed enclosure that held the blades true during manufacturing.

“What was really interesting about this approach is that shrouded impellers are, for most current additive technologies, basically untouchable because of all the traditional support structures they require,” says Velo3D’s Karesh. “We used a, not support-free, but reduced-support approach. Mohawk was saying, ‘we don’t need the shroud in the end, but the shroud makes our part better, so we’ll attach this thing that’s typically extremely hard to print – and just cut it off after.’ Using Velo3d’s technology, they were able to build that disposable shroud onto their impeller, get the airfoil and flow-path shapes they wanted, and then it was a very simple machining operation to remove the shroud.”

Surface finish was another focus. Says Mohawk engineer Rochelle Wooding, “The surface was a bit rough in our early iterations. What was interesting about the sacrificial shroud was that it gave us a flow path through the blades that we could use to correct for roughness using extrusion honing; it took some further iteration to determine how much material to add to the blades to achieve the required blade thickness that we wanted. The final surface finish we achieved is comparable to that of a cast part, and suits our purposes aerodynamically.” What’s more, all design dimensions enabling proper impeller operation were within tolerances.

Next steps are retrofitting AORBs with the new impellers and testing them in field conditions. “We expect that successful execution of these two tasks will fully demonstrate that 3D-printed Inconel parts delivered by LPBF technology are a viable and reliable alternative for manufacturing turbomachinery components,” says Cordova. Work is already underway using AM for other blower parts like housings and volutes.

Cordova is particularly proud of the professional credentials and work ethic of the two young engineers who’ve been engaged in these recent in-house projects.

“Through these DOE-funded projects, we’ve been able to develop a library of common parts, Wooding says. “Based on the original idea, we now have at least three completely different platforms that can serve different power capabilities to support progress for the clean energy of the future.”

mohawkinnovative.com

velo3d.com

This article was provided by Velo3D.