Product-development SMBs can take advantage of Web-based file sharing

Staff

General DPN For small and medium enterprises, or SMBs, CAD collaboration poses unique challenges. A product from an SMB has to be just as sophisticated as competing products from larger companies.

For small and medium enterprises, or SMBs, CAD collaboration poses unique challenges. A product from an SMB has to be just as sophisticated as competing products from larger companies.

Similarly, the development processes supporting that product have to be on par with those in the larger companies. This means that the smaller company’s product-development infrastructure will be competing along with the product itself.

The product may require a global design team with offshore manufacturing; it may need integrated mechanical and electronics subassemblies; and it may need to be re-designed, or at least updated, every six months. These needs must be supported by the infrastructure. The larger company is almost certainly going to have a product data management (PDM) repository to manage file versioning and team collaboration; the smaller company may not. The more complex the product, the greater the difficulty SMBs will experience in conducting effective collaboration.

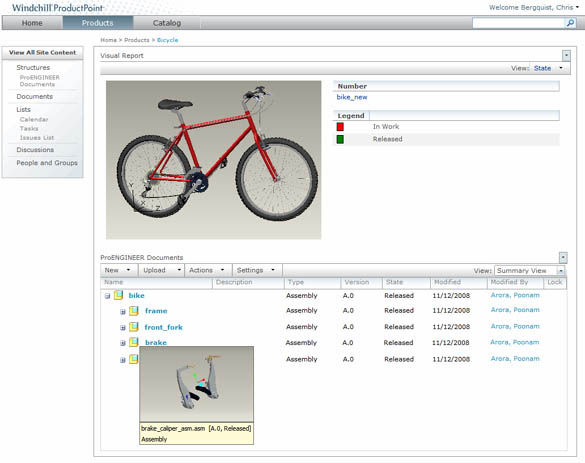

A typical PTC Windchill ProductPoint product home page. ProductPoint is based on Micrsoft’s SharePoint technology.

Collaboration, and in particular, file sharing – is key to competing through product-development, yet most SMBs are using less than adequate tools for sending and sharing files. Some work by email; others use shared network folders or FTP sites. Each presents significant problems:

• Search -Searching for a part from memory or by part number is a hit or miss proposition. A usable part file may or may not be identified based on the quality of the CAD database. The time spent searching and scanning for designs by part number and scanning paper documentation deprives a company of product excellence. Even if the most recently product part is located, it may not be the best variation to serve its purpose.

• Naming – Without an automated naming mechanism, smaller companies are forced to track all design changes manually, and to create an effective naming system for parts and assemblies. In practice, file names for parts and assemblies can become more random than consistent, as engineers resort to using their own names, file-save dates, original vendor part numbers, or other strategies to keep track of files.

• Versioning – Different users may be working on different components of the same assembly at the same time, so it is critical to keep track of the versions of files as they are checked in and checked out of the central repository. Also, it should be possible to roll versions back, because changes to one component may affect how other components function within the assembly.

• Conflicts – Without a multi-user conflict-resolution framework, shared files run the risk of introducing redundancy and errors into product designs, since it’s possible for multiple users to make conflicting changes simultaneously.

• Robustness -A part file may have relationships to five thousand other parts that make up a single assembly, and an assembly may have relationships with other parts and other assemblies. A CAD designer (or test or manufacturing engineer) should be able to see at a glance all dependencies of the part he or she is working on. For standard email, shared network folders, and FTP sites this is impossible.

{mospagebreak}Vendor Perspective: PTC

For the millions of users who have already adopted it, Microsoft’s SharePoint technology is bringing Web services to content management applications. SharePoint’s feature indexed search and other office-collaboration functions, but they stop short of satisfying the demands of CAD file sharing and collaboration.

Web-based CAD collaboration works best when tools include provisions for versioning, rich-content handling, and multi-dimensional search

What’s needed, and what is now available, is file-sharing software that can extend the capabilities of SharePoint for use with CAD-specific applications. This software, called Windchill ProductPoint by PTC, helps create a CAD collaboration infrastructure that can rival the product-development abilities of PDM-equipped companies.

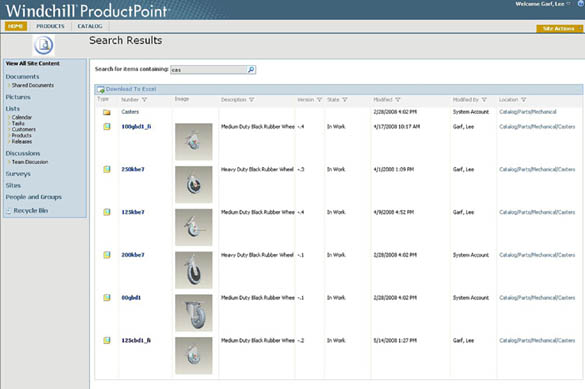

Windchill ProductPoint employs a robust versioning and mapping engine that tracks design histories and changing file dependencies. The software automatically increments new file versions, but otherwise lets companies implement their own file-naming schemes. A CAD-specific search engine makes it easy to find parts and assemblies by letting people search on metadata as well as conventional part names and numbers. For example, a design engineer could ask to see all parts supplied by a specific vendor; all parts that are attached to the rear axle; or all parts manufactured between April and June.

Lee Garf is Vice President Product Management, PTC.

For a video demonstration of Windchill ProductPoint, CLICK HERE.

www.ptc.com