Researchers 3D print with 2D materials to improve energy storage devices

By DE Staff

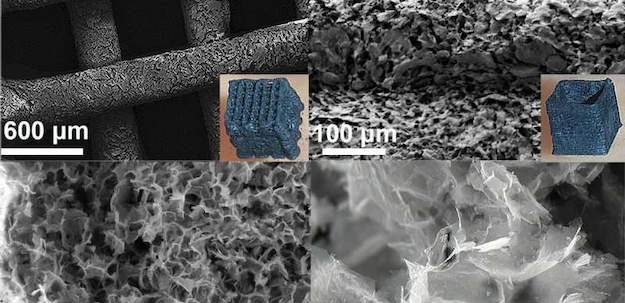

Additive ManufacturingUniversity of Manchester team uses MXene ink to additively manufacture supercapacitors.

(Photo credit: University of Manchester)

Like graphene, MXene is a two-dimensional material that is a ‘clay-like’ composite of early transition metals (such as titanium) and carbon atoms. As such, it demonstrates high electrical conductivity upon drying and is hydrophilic, which allows it to be turned into an ink suitable for additive manufacturing. As a result, the researchers say, these inks could be used to produce supercapacitors, which store more energy per unit volume or mass, recharge faster and tolerate more charge/recharge cycles than conventional rechargeable batteries.

“We demonstrate that large MXene flakes spanning a few atoms thick, and water can be independently used to formulate inks with very specific viscoelastic behaviour for printing,” said team leader Dr. Suelen Barg. “These inks can be directly 3-D printed into freestanding architectures over 20 layers tall.

“Due to the excellent electrical conductivity of MXene, we can employ our inks to directly 3D print current collector-free supercapacitors,” she added. “The unique rheological properties combined with the sustainability of the approach open many opportunities to explore, especially in energy storage and applications requiring the functional properties of 2D MXene in customized 3D architectures.”

www.manchester.ac.uk