Researchers developing multi-material for DLP 3D printing

By DE Staff

Additive ManufacturingIowa State and UCSB teams to develop photopolymer resin that uniquely solidifies to different wavelengths of light.

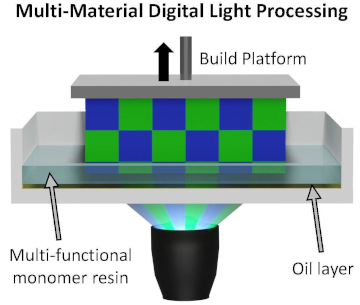

An illustration of a single resin producing two materials with different properties during light-based 3D printing.

(Image credit: Adarsh Krishnamurthy/Iowa State University)

Researchers at Iowa State University and the University of California, Santa Barbara (UCSB) say they are working on a way to enable a method to enable multi-material printing using the Digital Light Processing (DLP) process.

The inverse of typical FFF printing, DLP employs a light source that shines white light, projected as a 2D stencil, through the glass bottom of a vat of photopolymer resin. The thin, solidified layer is then lifted slightly from the glass bottom to allow liquid to fill the gap, as the next flash of light cures the subsequent layer, and so on.

The researchers are looking into varying not only the shape of the light projected but also its wavelengths. Paired with the right wavelength-sensitive resin, the process could selectively make precise regions of each layer stiff while making other regions flexible.

“We want to produce two material properties with the same resin,” said Adarsh Krishnamurthy, an associate professor of mechanical engineering and leader of the project at Iowa State. “That’s revolutionary in terms of materials for 3D printing.”

The Iowa State project is one of 37 that NSF announced in September as part of a four-year, $72.5 million investment to “create novel materials to address grand societal challenges and develop the scientific and engineering workforce of tomorrow.” The effort is part of the federal, multi-agency Materials Genome Initiative that’s focused on quickly advancing materials invention and use.

The program awarded Iowa State researchers $800,000 to use artificial intelligence and machine learning algorithms to help develop new resins which can be printed with different properties. The program also awarded UCSB researchers $1.1 million for their share of the project. Led by Michael Chabinyc, a professor of materials, the UCSB researchers will focus their work on polymer chemistry.

In addition to printing and testing actual materials, the researchers say they will develop a “digital twin” of the system, that can simulate and predict how different resins will respond to a spectrum of light wavelengths and exposures. The machine learning tools will help trim the list of potential resins suitable for development.

www.iastate.edu