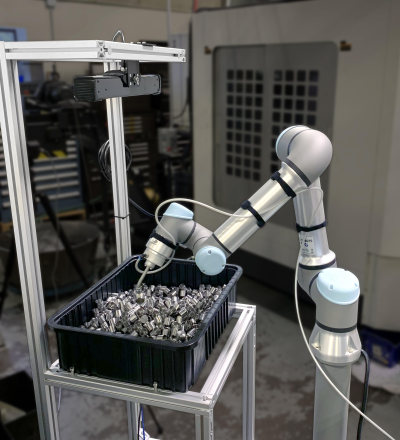

UR launches world’s first autonomous bin-picking kit for machine tending

By DE Staff

Automation Machine BuildingCobot firm’s ActiNav combines robotics with 3D sensor to simplify pick-and-place of parts to and from CNC machines.

Universal Robots (UR) revealed its ActiNav Autonomous Bin Picking kit that combines real-time autonomous motion control, collaborative robotics, vision and 3D sensors in an easy to deploy kit, to reduce the complexity of automated bin picking, the company says. According to the UR, the system doesn’t require vision or robotic programming expertise. Instead, it uses a “teach-by-demonstration” principle using a six-step, wizard-guided setup process integrated into the UR cobot teach pendant.

Universal Robots (UR) revealed its ActiNav Autonomous Bin Picking kit that combines real-time autonomous motion control, collaborative robotics, vision and 3D sensors in an easy to deploy kit, to reduce the complexity of automated bin picking, the company says. According to the UR, the system doesn’t require vision or robotic programming expertise. Instead, it uses a “teach-by-demonstration” principle using a six-step, wizard-guided setup process integrated into the UR cobot teach pendant.

“Machine tending has always been one of the mainstay applications for our collaborative robot arms,” said Jim Lawton, VP of Product and Applications Management at Universal Robots. “We discovered a significant market need for a simple solution that enables UR cobots to autonomously locate and pick parts out of deep bins and place them precisely into a machine. This is not pick and drop; this is accurate pick and part-oriented placement.”

ActiNav autonomously inserts parts into CNC or processing machines. The system pairs a high-resolution 3D sensor informed by CAD model matching, to enable high-accuracy picks. Powered by UR’s Autonomous Motion Module (AMM), the system determines how to pick the part, then controls the robot to pick the part and place it in a fixture. The autonomous motion control enables ActiNav to operate inside deep bins that hold more parts.

ActiNav works with UR’s UR5e and UR10e e-Series cobots, a UR+ component or user-defined end effector, and application-specific frame or fixture as needed. The kit includes the company’s Autonomous Motion Module and ActiNav URCap user interface software, along with a choice of 3D sensors.

www.universal-robots.com