Airbus, Addup deliver the first metal 3D printer to operate in space

By DE Staff

Additive Manufacturing AerospaceESA to test performance of metal disposition process in microgravity on the ISS.

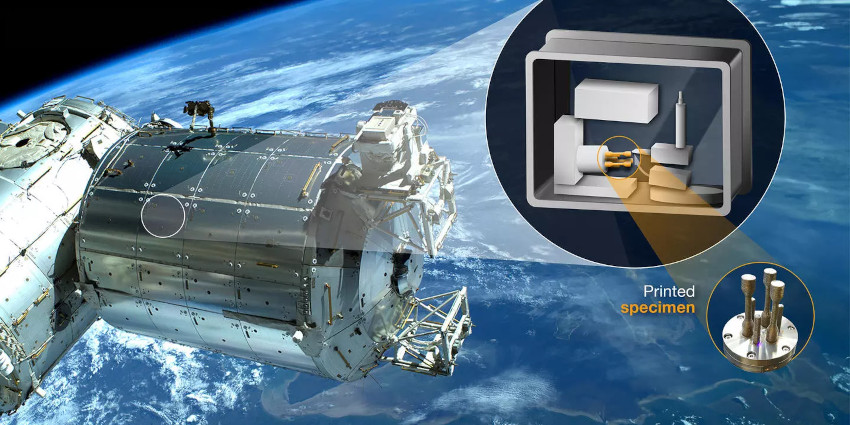

ISS’ Columbus European Science Module will host the AddUp/Airbus developed metal 3D printer experiment. Parts printed in space will be compared to reference parts produced before launch.(Photo credit: Airbus/ ESA/NASA)

Metal AM OEM, AddUp, and Airbus Defence & Space, announced the delivery and launch of the first metal 3D printer to operate in space to the European Space Agency (ESA). Developed by AddUp, and Airbus under a contract with the ESA, the metal 3D printer was designed to test 3D printing’s ability to perform metal disposition under sustained microgravity conditions.

On January 30, the printer was launched by NASA to the International Space Station and printing operations are expected to start in late February or early March, the ESA says.

The metal 3D printer will be installed in the ISS’ Columbus European Science Module, alongside other experiments carried out by European teams. Four part models will be printed in the Columbus module, which will then be returned to Earth and compared with the parts printed by the same machine on Earth before launch.

The ESA aim is to increasing the self sufficiency of the space station by enabling astronauts to manufacture spare parts directly in space. The technology could also reduce the prohibitive transport costs of delivering spare parts from Earth, which can take up to 12 months to arrive.

www.airbus.com

addupsolutions.com