FDM 3D printers produce unique fingerprint, researchers find

By DE Staff

Additive ManufacturingUniversity of Buffalo study develops ID technique that’s accurate 92% of time.

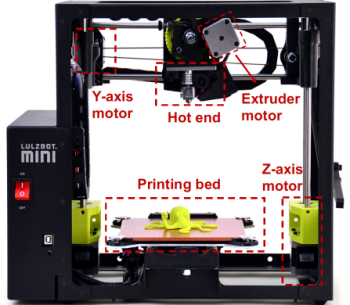

(Photo credit: University of Buffalo)

Each hot end on an FDM printer’s extruder has a unique thermal signature or “ThermoTag”, says Zhanpeng Jin, PhD, associate professor in the Department of Computer Science and Engineering at the University at Buffalo. By analyzing the small flaws and other characteristics a hot end imparts to a 3D printed model, it’s possible to determine if a particular 3D printer created the part.

To test the theory, Jin’s team printed the same model using 45 different extruders and created a database of each hot end’s thermal tag. By examining subsequent 3D printed parts, the team was able to correctly identify which extruder the mystery part had come from.

In a paper, “ThermoTag: A Hidden ID of 3D Printers for Fingerprinting and Watermarking,” recently published in the journal IEEE Transactions on Information Forensics and Security, the research team show how this phenomena could be used to create a registry of extruders to help curb product counterfeiting and use of 3D printers to create illegal “ghost guns.”

“This ThermoTag will behave like the fingerprint of the 3D printer. When you print out a new product, you can use watermarking,” Jin says, adding that watermarking can embed information, like printer manufacturer and a serial number, in the product itself. “So that would make this watermark of this particular product unique.”

www.buffalo.edu