Sticky Business

By David Gersovitz

Automation Machine BuildingHow Innovative Automation gambled and won launching a serial product, the RoboTape.

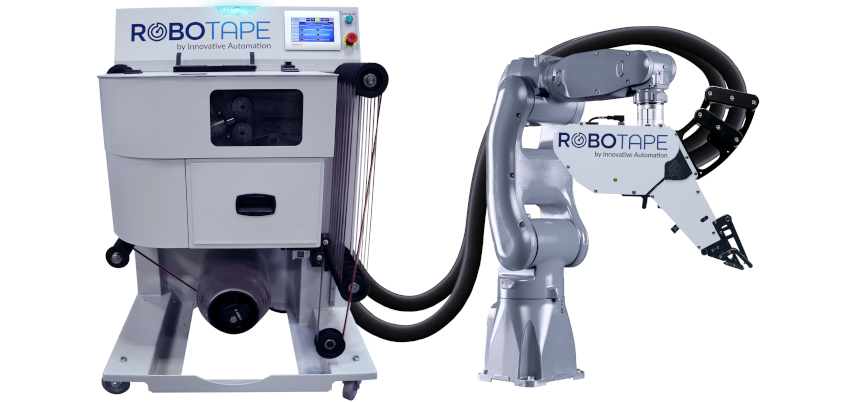

Innovative Automation’s RoboTape system features a versatile remote tape feeding design that separates the Payout (left) from the Applicator (right), which can be mounted to any articulated robot.

(Photo credit: Innovative Automation)

If a Canadian manufacturing success is the culmination of a journey, then Barrie, ON-based Innovative Automation has taken a path rarely traveled. It’s seldom that a custom machine builder creates a serial product, let alone one now garnering sales worldwide. But that’s the path the custom machine builder chose when it developed RoboTape, an automated system for feeding and installing adhesive-backed foams, felts and attachment tapes

In the four years since development began, the RoboTape system has generated several million dollars in orders, led to a collaboration agreement with global tape manufacturer, 3M, and is now fast approaching 100 units installed in the field.

Given that success, RoboTape’s manufacturing footprint became too large for Innovative’s Barrie, ON facility last year, when production was shifted to a second facility in Newmarket. Even so, production may outgrow that facility within 2-3 years, says Innovative Automation president, Michael Lalonde, who co-owns the company with CEO Stephen Loftus.

With more than 200 employees, Innovative is hardly a mom-and-pop shop. However, developing a serial product is a different beast than producing one-offs. It requires direct sales and support strategies extendable worldwide, as well as a professional marketing campaign. Add to that the budgeting and billing for continuous production and managing a large parts inventory, plus legal requirement, such as contracts, warranties and patent filings.

A Familiar Path

Prior to RoboTape, Innovative had followed a familiar path. From its founding in 1989, it focused almost entirely on custom automation for the automotive sector, later diversifying into medical devices and consumer goods. By the late-2010s, Innovative’s growth allowed for the creation of a small R&D department, Lalonde says.

Innovative had built foam taping machines for a customer, but it was still a custom product, pre-cutting the tape, then picking and placing it. Later on, Lalonde and a colleague were brainstorming about leveraging the experience gained from that project.

“We looked at each other and said, ‘Wouldn’t it be great if we could make the cut in the [robotic] head, and how can we get the tape to the head and make it a flexible system for any project?’”

From the outset, Innovative knew there was enormous market potential for the RoboTape system. For one, global sales of technical tapes used in manufacturing are expected to double this decade, most such adhesives – whether for joining, insulating, bonding or glazing – but are still applied manually.

The largest market is automotive, where pressure sensitive tapes are used for bonding and sealing, noise and vibration reduction. Current RoboTape customers include Tier 1 and 2 automotive suppliers, appliance manufacturers and consumer goods. According to Gary Yearwood, RoboTape business unit manager, architectural products are a potential new frontier, along with electronics, HVAC and aerospace.

One of the system’s primary advantages, Yearwood says, is that it can apply tape faster than humans – up to 300mm/s – with better repeatability and less waste.

From left: Gary Yearwood, RoboTape Business Unit Manager; Sean Robillard, lead electrical engineer; Michael Lalonde, President and co-owner of Innovative Automation; Ray Reginato, Festo Canada’s Industry Segment Specialist for electronics and assembly.

(Photo credit: Innovative Automation)

In contrast, automated taping competitors all have significant limitations. Some can only apply one type of tape, only tape in straight lines or it must be purchased with a particular robot.

Others use pick-and-place technology, which tends to be slow and can damage the tape during application. If the tape supply is mounted on the robot, production must stop whenever a new supply is needed and requires a larger robot and therefore larger footprint for the work cell.

Choose your Partner

In addition to its own exceptional in-house talent, Innovative Automation also leveraged its longstanding relationship with Festo Canada to create RoboTape. Selected early on as the project’s pneumatics supplier, Festo provided trial parts and, ultimately, many critical components.

Trial parts helped the machine builder limit its financial exposure during concept development. It also allowed Festo to demonstrate how its components, like its fluidic muscle, could help meet critical design and performance objectives for the initial production model.

“We chose Festo because I knew they would have everything we needed,” says Zac Cutt, mechanical engineer and lead machine designer. “As a bonus, Ray [Reginato, Festo Canada’s Industry Segment Specialist for electronics and assembly] was available to us. Having him suggest the smallest versions of everything, as well as the fluidic muscle, was really helpful.”

Festo’s DMSP fluidic muscle made sense for the initial model’s end effector. Mimicking the movement of a human muscle, the actuator’s rubber-sheathed polymer tubing can exert 10 times the initial force of a similar-sized conventional pneumatic cylinder, in this case, actuating the blade that cuts the tape.

Maximizing Versatility

From the get-go, the goal was to make RoboTape a more versatile system. Those who have compared it to its nearest competitors “tell us those systems have their place, but none comes close to RoboTape,” says Yearwood.

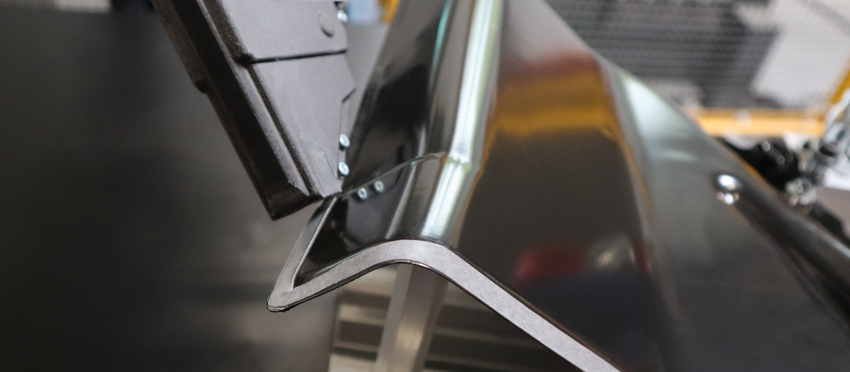

Each RoboTape can be programmed with multiple recipes, for single or double-sided flat, foam or felt adhesives, with simple or complex geometries with gradual or sharp curvature.

According to Cutt, RoboTape’s lead engineer, developing the software interface with so many different parameters, recipes, speeds and feeds, while also factoring in the subtle differences of various tapes, and then debugging the system so it all meshed together nicely, was a two-and-a-half-year project.

Capable of a feed rate up to 300mm per second, RoboTape’s end effector can deftly handle complex contours and geometries.

(Photo credit: Innovative Automation)

From the Payout, a patented feed system delivers tape (up to 7 meters away) to RoboTape’s Applicator, which performs the peel/affix/cut functions. The system also returns the discarded adhesive liner to the payout for disposal.

According to the company, this remote feeding concept was the biggest design challenge, but also the biggest benefit. For example, due to remote feeding, the R&D team was able to minimize the Applicator’s size and weight. As a result, the system’s end effector can swivel to dispense tape in any direction.

The remote feeding approach also means the system isn’t tied to any one robot vendor. The end effector can be mounted on any articulated robot, even a cobot, or mounted in a fixed position.

In addition, since the Payout will almost always be positioned outside the robot’s safety zone, a new spool can be loaded and spliced without interrupting production. Remote feeding also helped keep the RoboTape’s two main components compact overall, enough to fit any customer layout.

Stage Gate Process

RoboTape’s development adhered to the Stage Gate Process, moving from initial concepts to prototyping of individual functions like feeding and tape-cutting, says Lalonde. For example, several methods of cutting tape were considered, from lasers to knives to spinning blades. Only when the overall concept was approved, did product design begin.

“We had to pass the milestones required with each gate before making further investment,” Lalonde says. “We chose to have a dedicated team lead the development of RoboTape because we knew, if we tried to pick away at this as a side project, other projects would always take precedent.”

Soon after RoboTape’s public reveal, its social media campaign began generating several inquiries a week from around the world. For example, RoboTape videos on LinkedIn caught the attention of 3M tapes experts, who initiated a dialogue followed by months of testing of 3M products.

“3M wanted a tight start/stop tolerance as well as a tight bend radius, and in both cases, we far exceeded their requirements,” says Sean Robillard, RoboTape’s lead electrical engineer.

The company says RoboTape meets 3M’s 5-point check for limited tape stretch, accurate tape wet out, splice identification and disposal, successful liner handling and repeatable tape placement accuracy. For 3M, the collaboration is an opportunity to sell more tape, Lalonde says.

“They’re competing against other joining technologies like riveting, gluing and fastening that have been automated for 30 or more years,” he says. “RoboTape gives 3M the opportunity to offer the same level of automation as those other technologies, but with the benefits of tape.”

For Innovative Automation, the collaboration extends RoboTape’s sales and marketing reach via the 3M tape sales force.

Whatever is next for RoboTape, the Ontario machine builder says more complementary products are coming soon.

innovativeautomation.com

www.festo.com/ca

This story was supplied by Festo.