Pushing the AM Envelope

By Siemens

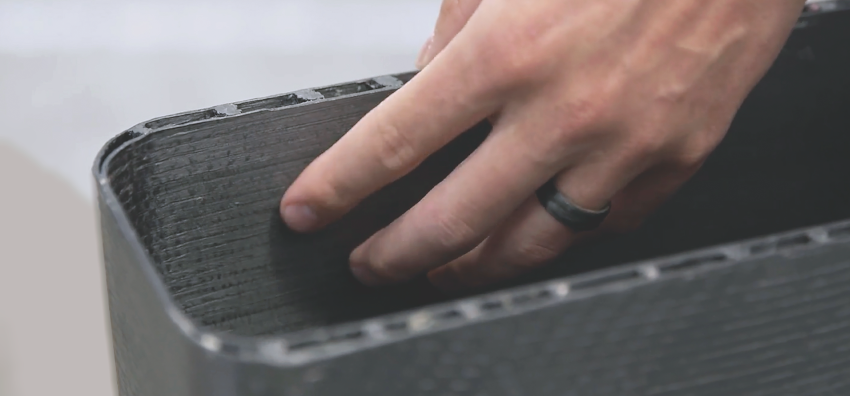

Additive Manufacturing Machine BuildingElectroimpact’s SCRAM system enables 3D printing of fiber-reinforced aerospace-grade components.

Electroimpact’s SCRAM system combines an in-situ out-of-autoclave thermoplastic Automated Fiber Placement (AFP) process, a Fused Granulate Fabrication (FGF) 3D printing process and subtractive machining.

(Image credit: Electroimpact)

The Seattle-area company’s system combines an in-situ out-of-autoclave thermoplastic Automated Fiber Placement (AFP) process, an advanced Fused Filament Fabrication (FFF) 3D printing process, a Fused Granulate Fabrication (FGF) 3D printing process, and subtractive machining into a unified Scalable Composite Robotic Additive Manufacturing (SCRAM) system. The result is an industrial, 6-axis continuous fiber-reinforced 3D printer that enables tool-less rapid fabrication of aerospace-grade composite structures.

True 3D Printing

Most 3D printing processes are more accurately described as 2.5D printing. The material is deposited successively in flat slices that, when stacked together, form a 3D object.

In contrast, the SCRAM process renders true 3D printing. The system is an integration of multiple additive and subtractive processes, enabled by Electroimpact’s patented robot, a rotating build platform in a climate-controlled build chamber.

Layers of continuous fiber-reinforced thermoplastic are crafted into shapes with complex contours, including aerodynamic surfaces and ducts for fluid flow. As a 6-axis process, fiber orientation within each layer can be tailored to the specific application, providing optimal strength and appropriate stiffness distributed throughout the part, much like a conventional AFP system.

In addition to the continuous fiber-reinforced thermoplastic printing process and the FGF support tool printing process, SCRAM cells are also fitted with two FFF nozzles optimized for deposition of thermoplastic material reinforced with short or “chopped” fiber.

A proprietary laser heating system is incorporated, producing exceptionally strong bonds between layers. This process is ideal for situations in which layering continuous fiber is geometrically impossible or otherwise doesn’t make sense.

“It allows us to deposit the material exactly where it needs to be and only where it needs to be, achieving the highest possible strength and lowest weight,” says Ryan Bischoff, senior composite engineer at Electroimpact.

This is a true 3D printing process where the layers are not simply a stack of planes. Complex geometries such as variable density core and other internal structures can be printed directly onto continuous fiber-reinforced layers with widely varying curvature. If desired, additional continuous fiber-reinforced layers can then be deposited on top of the chopped fiber-reinforced core structure, forming an upper skin.

Factory in a Cell

“Electroimpact expanded from doing mostly drilling and fastening to additive manufacturing about 15 years ago,” Bischoff says. “That move, and the advancements over the years, led to the development of a system that we call a ‘factory in a cell.’ Instead of needing a whole assembly line, with each dedicated machine only performing a single function, it is one system, which can be printing ducts for jet engines one day and a wing component the next. It can be quickly changed and adapted according to needs.”

Ryan Bischoff, Electroimpact engineer, discusses the capabilities of the SCRAM system for prototyping and low volume production of complex carbon-fiber components.

(Photo credit: Electroimpact)

“Here is where the factory-in-a-cell helps teams develop parts much more quickly than a traditional facility,” Bischoff says. “You complete the whole process within the SCRAM system. It makes sense because these are not the kind of parts that are produced in the thousands.”

“Our customers are doing extraordinary work, and we are right there alongside them,” he adds. “Your Electroimpact engineer is with you though the lifespan of the system for all questions and requests. We are here to help builders push boundaries. We service our equipment till the day it dies. Support is one of the things Electroimpact does better than anyone else in the industry.”

With the SCRAM system, 3D printing replaces the need for the traditional complex tooling development typically used for automated carbon-fiber layup. This eliminates the inflated cost and time investments needed in traditional tooling and development; therefore, the SCRAM system allows for faster corrections and modifications.

Once the complex tooling is printed, the SCRAM system changes to a multi-axis milling head that finishes the form to exacting specifications. It then changes once again to the 6-axis carbon-fiber placement head and applies the intricate pattern of carbon fiber tape to the support material. Bischoff explains that the tape is deposited quickly, establishing the form. Next, the additive support material is then dissolved away, leaving behind a component in the exact shape needed.

“We are working to make an open system that will support the material choices and make the parts each customer needs. We are driven by customer demand,” Bischoff explains.

To facilitate the quick change over between multiple 3D printing operations, plus the subtractive milling process, while enabling the complex and accurate motion paths of the printer, Electroimpact’s SCRAM relies on the SINUMERIK ONE from Siemens. According to the company, the CNC control system is ideally suited to the SCRAM’s ability to shift from 3D printing to finishing and continuous carbon-fiber placement, all from one control.

“The faster processor times for both motion control and PLC, combined with new functionalities of the SINUMERIK ONE, further enable the incredible work Electroimpact is doing with the SCRAM system,” says Steve Czajkowski, engineering manager at Siemens.

Brian Cubie, account manager for Siemens, agrees. “Our system is the foundation on which they are building, and it is just incredible to experience,” he says. “I have been in robotics for many years, and to see what the engineers at Electroimpact are doing in terms of digitalizing the factory floor is exciting. They are always at the forefront. Electroimpact does a phenomenal job of taking our new SINUMERIK ONE control and adding encoders for feedback and run it though their own kinematics.”

Digital Twin

Looking to the future, Electroimpact says the SINUMERIK ONE control platform will allow the company to implement advanced digital twin technology into its SCRAM system. The company says this will help its teams engineer a fully functioning machine even before a real-life prototype exists and for teams to transfer tasks from the real world to the virtual environment. It will also keep projects moving consistently to the work preparation phase.

The SCRAM system provides a true 3D printing process, where the layers are not simply stacked on top of each other. The 6-axis tool paths place continuous fiber filament as well as chopped fiber.

(Photo credit: Electroimpact)

“There‘s a huge industry push to having a digital twin,” Electroimpact controls engineer, Martineau, says. “I am extremely excited about supporting SCRAM in our customers’ endeavors moving forward. Each customer is pushing what is possible. They are reaching for ideas that are slightly out of the ordinary. With this true digital twin, instead of needing to travel for an on-site visit or asking for photos or video footage of their challenges, the PLC will allow simulation right inside the control.”

Just as customers can run the digital twin from their computer, Martineau says she will be able to operate the digital control of a customer’s SCRAM right from hers.

“We hear from customers when they’re striving for the next level, pushing the system to the max. Being able to jump in and see what’s happening is so valuable,” she says. “The digital twin capabilities of SINUMERIK ONE will enable us to work extremely close to our customers in the future, supporting their desires to push the envelope of product development. With digital twin technology this accurate, customers will benefit from knowing we can jump in anytime to seamlessly help troubleshoot.”

Siemens and Electroimpact have been partners for more than 10 years. The SCRAM previously included the SINUMERIK 840D sl, a precision CNC control favored by the aerospace industry. SINUMERIK ONE is faster and excels at more complex code.

“Electroimpact is always pushing the envelope,” says Brian McMinn, head of the Siemens Machine Tool Systems business. “Their approach is to always be at the very leading edge of manufacturing technology. We are glad to be a part of their team as SINUMERIK ONE has the power and speed to make it all possible.”

www.electroimpact.com

https://usa.siemens.com