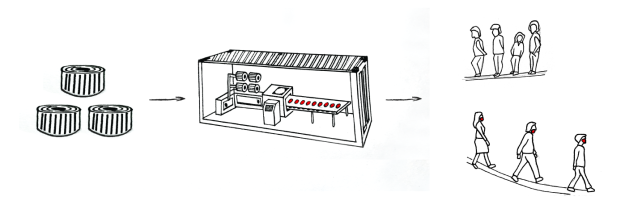

Open-source mini-factory cranks out 50 facemasks per minute within shipping container

By DE Staff

Automation Medical editor pickProject CAROLA partners Mikron, Festo unveil mobile automation system to address global PPE shortage.

(Photo credit: Project CAROLA)

Mikron’s automation system is the culmination of Project CAROLA, a non-profit initiative to address the global facemask shortage. Using the project’s open source design, engineers worldwide can construct as many of these containerised mask-making systems as needed and place them in remote areas or near locations with the highest demand (e.g. hospital, school, shopping center).

The open source nature of the project also allows for the base system design to be adapted to suit specific installations or needs, with the specifications being made be available to the general public. According to the project, the design is published under the CERN Open Hardware License 2.0, updated in March 2020 to broaden the legal framework to include application-specific integrated circuits (ASICs) and field-programmable gate arrays (FPGAs) as well as a wider range of open hardware applications.

(Photo credit: Mikron)

In addition to the production line inside, Mikron’s containerized system integrates air-conditioning with air purification filters to reduce the risk of viral contamination. It can make individual masks or shrink-wrapped packs of ten thanks an automated station developed by fellow Project CAROLA partner, pi4–robotics GmbH.

Project CAROLA partner organizations include CADUS e.V.; Open Source Ecology Germany e.V. and r0g, the agency for open culture and critical transformation, as well as corporate supporters Mikron, Festo, pi4–robotics and Wikifactory.

www.projectcarola.org