Brought to you by SPIROL Connecticut

Benefits of 420 Chrome Stainless Steel Coiled Spring Pins

By Michael Pasko, Applications Engineer

March 1, 2024 in General

Coiled Spring Pins are offered in light, standard and heavy duty to meet application-specific requirements. (Photo: SPIROL)

Coiled Spring Pins are offered in light, standard and heavy duty to meet application-specific requirements. (Photo: SPIROL) SPIROL invented the Coiled Spring Pin in 1948. Coiled Pins are used in many industries including: automotive, medical, heavy equipment, military, aerospace, and consumer products. In applications requiring a combination of high strength, superior fatigue life, and corrosion resistance, 420 martensitic chrome stainless steel offers a host of technical benefits and provides an overall robust cost-effective solution.

Strength

SPIROL’s 420 stainless steel Coiled Spring Pins are hardened to values approximating their high carbon steel equivalents and share the same minimum rated shear strength. This process also develops desired spring properties and fatigue resistance. Chrome stainless steel Coiled Pins also offer good corrosion protection against most common atmospheric and environmental conditions without the risk of rapid work hardening associated with 302/304 austenitic stainless steel. In most cases, 420 chrome stainless steel Coiled Spring Pins may be used as drop in replacements for high carbon steel pins assuming galvanic potential has been considered relative to the host material.

Corrosion Resistance

When corrosion resistant Spring Pins are required, there are (2) common options:

- Carbon steel with a sacrificial protective plating or coating

- Stainless steel alloys which are inherently corrosion resistant

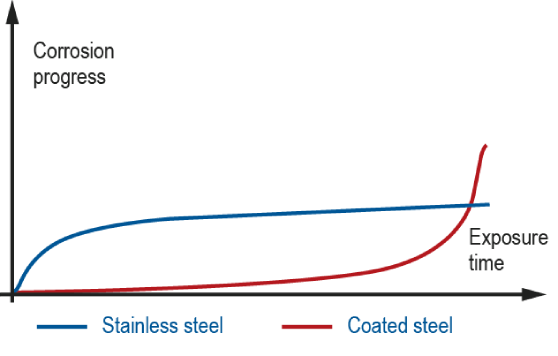

This graph shows how time impacts the corrosion resistance of coated steel compared with stainless steel

Platings and coatings provide excellent performance though they are consumed over time, whereas stainless steel provides a lifetime of protection providing free oxygen is available in the environment (free oxygen allows the fastener’s protective chromium oxide layer to reform if damaged). For plated and coated parts, once the plating or coating is depleted, the carbon steel is left unprotected and rapidly corrodes.

420 martensitic chrome stainless steel provides good corrosion resistance in environments, including but not limited to:

- Normal atmosphere and humidity

- Steam

- Fresh water

- Alcohol

- Ammonia

- Alkalis

- Mild acids (ex. carbonic)

- Petroleum products such as gasoline, oil, crude, etc.

- Mild detergents & sterilizing solutions

While 302/304 austenitic stainless steel Coiled Pins provide excellent corrosion protection, this material is not an appropriate solution when the pin will be subject to dynamic loads, or where strength and fatigue resistance must equal or exceed that of high carbon steel. Alternatively, 420 martensitic chrome stainless steel provides an exceptional combination of strength and fatigue resistance – in addition to its inherent corrosion resistance.

Fatigue Life

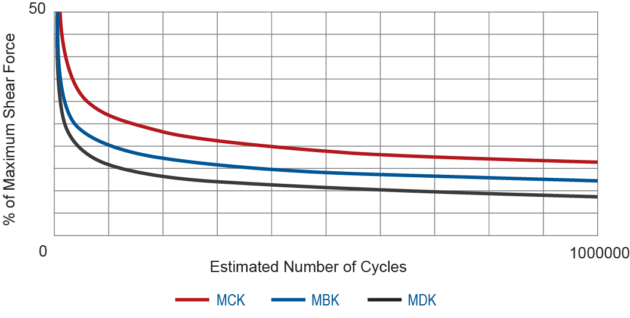

420 chrome stainless steel provides enhanced fatigue life – an important consideration given that Coiled Spring Pins are often intended to function as dynamic elements within many applications. A unique characteristic of Coiled Spring Pins is that their flexibility after installation protects host holes and assemblies by dampening vibration and shock loading. For the purpose of comparison, Coiled Pins of the same duty (i.e. material thickness) produced from material of equal dimensions, were tested in the three standard materials:

MBK – Standard duty, high carbon steel, plain finish

MCK – Standard duty, 420 chrome stainless steel, plain finish

MDK – Standard duty, 300 series austenitic stainless steel, plain finish

Data for comparative purposes only – Conditions in this test do not infer performance benchmarks in any application as varied load, host materials, hole size, and shear plane quality/clearance will impact performance

Resultant trend lines demonstrate 420 chrome stainless steels superiority in fatigue when tested at increasing percentages of assigned minimum double shear strength:

Summary

Coiled Spring Pins manufactured from 420 chrome stainless steel are an excellent material choice where high strength, moderate corrosion protection, and superior fatigue life are critical. Additional benefits to consider include:

- Excellent cost / benefit relationship in performance applications

- High wear resistance

- Good tensile and creep strength at moderately elevated temperatures

- Oxidation & erosion resistant

- Improved component cleanliness as compared to high carbon steel

- Reduced potential for mixed product & debris as compared to plated and coated carbon steel product