Autodesk forges its road forward

By Ralph Grabowski

CAD/CAM/CAEAutodesk stresses the importance of its Forge technology at AU 2021 as the company struggles to implement the cloud-based APIs.

Autodesk executives, including VP of Design and Manufacturing Stephen Hooper, recorded presentations for AU 2021’s virtual event.

(Photo credit: Autodesk)

Never mind that Autodesk has been talking up collaboration ever since Carol Bartz was CEO in the mid-1990s; that the cloud is the norm for everyday people; and that every CAD vendor promises to save designers time.

All for Forge, and Forge for All

To understanding Autodesk strategy going forward, its Forge technology is key. Originally, Forge referred to Autodesk’s since-abandoned 3D printing API (application programming interface). Since AU 2015, however, Forge has refer red to Autodesk’s platform of web service APIs. According to the company, these web services are akin to Lego blocks that developers can combine to create design workflows and/or embed components of Autodesk online products into their own applications.

Autodesk sees its Forge APIs as the center for all its applications’ design data.

(Photo credit: Autodesk)

Autodesk sees Forge as useful for writing add-on software that visualizes data, automates design processes and connect teams with workflows. One example is Forge’s Model Derivative API. With it, files uploaded to Autodesk’s A360 servers can be translated to 60 other data formats, including generic ones like STL and STEP.

As a application example, an architectural firm could work with Forge APIs to create a workflow in which a building design would be uploaded to A360 to share it with clients securely. Clients would then view the design in 3D and 2D, and drill down to specific properties of the building’s parts; meanwhile, graphs would show statistics like square footage and/or types of components per floor.

For Autodesk, it dreams of a day when all its programs are rewritten in Forge. The file formats its various applications create (and the incompatibility problems that result) would disappear and all their applications would be able to intercommunicate data freely and incrementally.

Forge is so important that executives at AU called it “the Autodesk platform.” Moving data between Autodesk’s myriad of data-incompatible programs is, however, a long-haul project. Initial efforts began around 2008 in getting Inventor and AutoCAD to talk to each other. Subsequently, Autodesk released the “universal” Navisworks viewer, but it didn’t quite make the grade.

And so around 2018, Autodesk turned to Forge to solve its translation problem. It turns out, however, that the Forge-ian dream is not yet fully realized. Autodesk is still in a liminal stage of its implementation.

“We’re investing heavily in connections across Autodesk products, improving interoperability,” said VP of the AutoCAD family of products, Rob Maguire, speaking in the present-continuous tense.“We’re excited about the potential this has… With Forge, we’re making strides towards fluent workflow capabilities.”

While Forge is crucial; it’s not yet pervasive. Until it is, Autodesk Docs (formerly BIM 360 Docs) will have to act as the placeholder. As a web-based application, Docs lets users view, markup and manage files in many formats, and is integrated (so far) into AutoCAD and Revit.

What’s New in AutoCAD

As Autodesk scrambles to interconnect AutoCAD with its other incompatible software, its competitors are already there. Graebert (ARES), Hexagon (BricsCAD), and Nanosoft (nano CAD) took the easier route by unifying general, mechanical and architectural designs within a single program and storing models in DWG files, albeit with proprietary extensions. As a result, those applications don’t suffer from a data compatibility problem.

At AU 2021, the brief AutoCAD-specific keynote described some features added to last year’s release, such as Trace (for marking up drawings collaboratively) and Count, another way to count entities in drawings.

For the future, Autodesk promises AutoCAD will get automated drafting workflows, such as Connected Paper, which recognizes markups that were hand sketched or added to PDF files, and then converts them to AutoCAD geometry. In addition, AutoCAD Automation will suggest combining repetitive command sequences into a single macro and My Insights will let users see how they employ AutoCAD, and then suggest alternative commands that might be more efficient.

What separated AutoCAD from its competitors in the 1980s was that it allowed users to customize the CAD program on their own. Other systems at the time, like Intergraph and Computervision, charged customers big bucks for customization. For today’s users of the next generation, web-based version of AutoCAD, that level of customization won’t be possible for the foreseeable future. Autodesk says that users will “perhaps someday” be allowed to embed their in-house applications in the browser version of AutoCAD.

What’s New in Fusion 360 and Inventor

The start of the mechanical keynote at AU treated us to a liturgy of gloom: “The cost of doing nothing is too high,” said VP of Design and Manufacturing Industry Strategy, Srinath Jonnalagadda. “Continued reliance on home-grown data management systems perpetuates the ongoing struggles in the supply chain… Not dealing with complexity can lead to lost profits and opportunities.”

The solution is, of course, to employ Autodesk to “empower innovators everywhere.” But even so, Jonnalagadda noted that the complete solution – a single cloud platform that unifies all tools from concept to manufacturing – lies in the future: “And that is what we’re working towards with Autodesk Forge Platform.”

Fusion 360 generatively modifying a model following heat and electrical analysis.

(Photo credit: Autodesk)

Fusion 360 isn’t, however, like PTC Onshape or Graebert Kudo, where users log-in from a browser on any hardware. Instead, Fusion 360 requires an 1.9GB download and then it runs only on Windows or MacOS. That there is a free version for anyone’s personal use, which suggests it’s not selling well.

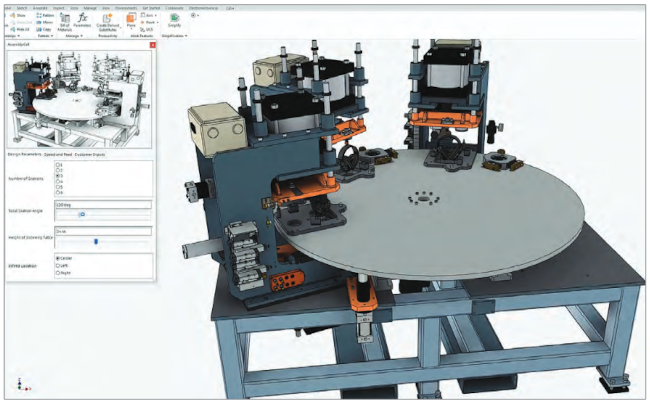

New in Fusion 360 is the ability to add parametrics to imported meshes and convert them to solids. Sub-division modeling is now also parametric. Other new features include variable patterns (non-uniform arrays), library-based electrical schematic designs inside mechanical models, electromagnetic simulation from ANSYS, and plastic simulation from MoldFlow. What I found particularly interesting is a new form of generative design that changes models following the results of simulations.

Although Autodesk hopes customers will switch to Fusion 360, the company continues to update Inventor for desktop users.

(Photo credit: Autodesk)

Autodesk has lots of plans for our data. It is thinking of using AI to generate design concepts, to detect repetitive design work and to report underused production machines.

This sort of data mining isn’t as easy with desktop-only CAD. But, as other CAD vendors have found, desktop MCAD is what customer prefer, and so Inventor managed to get a mention during the AU keynote speech. It can now use multiple CPU cores to open, edit and update models faster. Also new this year is selective import from Revit files, so that machines models are associated with building models.

“This is an approach we’ll be developing across the rest of our entire portfolio in the coming months,” explained VP of Design and Manufacturing, Stephen Hooper, “bringing Fusion, Inventor, AutoCAD, and even Revit data to the Forge Platform.” While Autodesk pins its future on Forge, the company’s progress in Forge-ifying its software appears remarkably slow. Each year we hear how it’s going to be great, making me wonder in which year of AU the company finally announces that its programs are islands or isthmuses no longer.

Autodesk is nevertheless emphasizing how Fusion 360 puts data at its center, and at the center of customer-corporations involved in manufacturing. As the Forge API connects the program with third-party software, Autodesk aspires to make Fusion 360 the umbrella for all industry.

So far, the brightest point is Fusion 360, and it does well proving what Forge can do. I expect that the long-promised cloud version of AutoCAD is being rewritten in Forge. Or, maybe just maybe, they’ll shift to a new underlying paradigm and start over.

www.autodesk.com

Ralph Grabowski writes on the CAD industry on his WorldCAD Access blog (www.worldcadaccess. com) and weekly upFront.eZine newsletter. He has authored numerous articles and books on CAD, Visio and other design software applications.